Seat Design

Aircraft and Automotive Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Vibration, and Crash Test

Seat Design

Artificial Intelligence Analysis

FEA|CFD & AI Integration

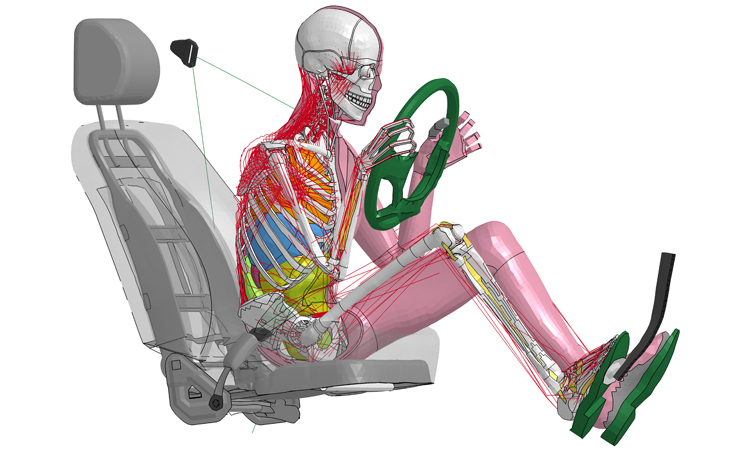

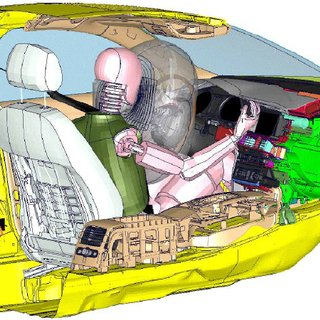

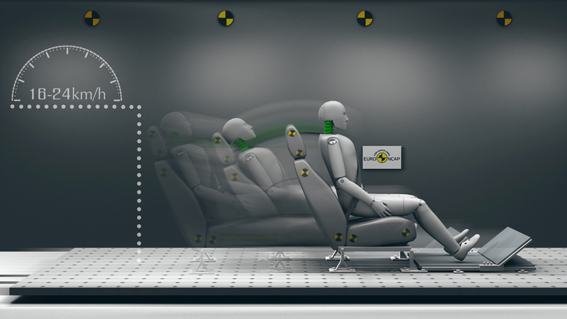

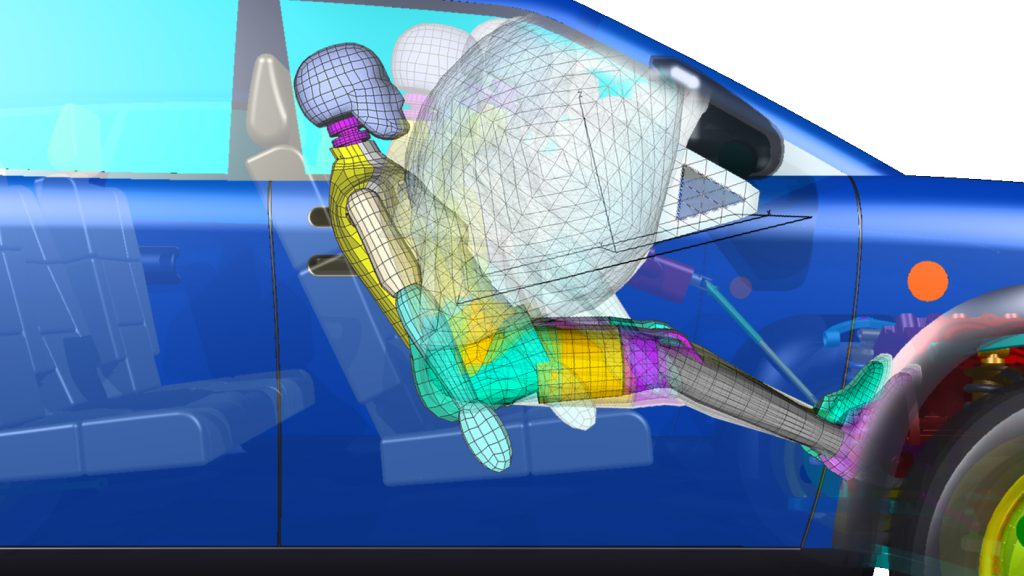

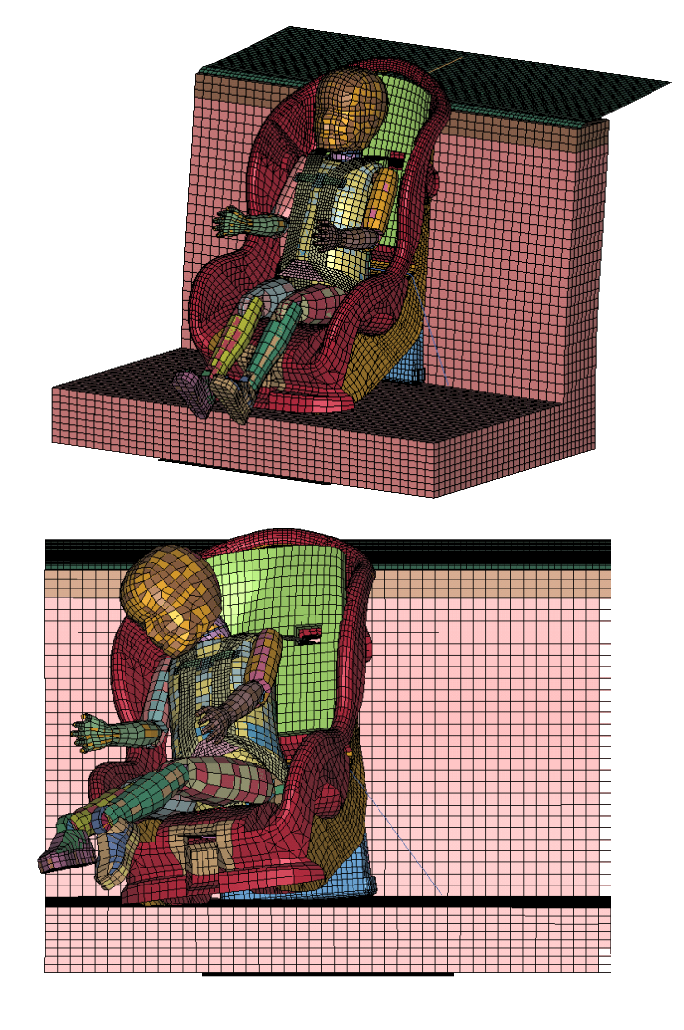

The use of Finite Element and CFD-based design solutions can provide significant benefits for seat design in the automotive industry. By using this tool, manufacturers can anticipate manufacturing issues and ensure just-in-time delivery, reducing costs and improving efficiency. The ability to meet regulatory requirements is also a key benefit, as virtual testing can help to ensure compliance with safety standards such as EuroNCAP, JapanNCAP, China C-NCAP, NHTSA (National Highway Traffic Safety Administration) and IIHS (Insurance Institute for Highway Safety).

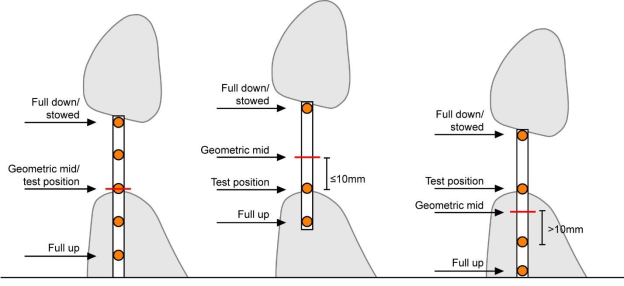

Finite Element and CFD-based design can help ensure the right occupant posture, which is essential for safety, static and dynamic comfort — for example, by predicting the H-Point and incorporating whiplash, thermal and acoustic comfort simulation.

The ability to predict the comfort of innovative seat designs using a combination of advanced design and simulation tools, a library of human models, and our team’s experience in CFD (Siemens Star-CCM+, Ansys Fluent, OpenFOAM) and FEA (Ansys LS-DYNA, Simulia Abaqus, ESI Pam-Crash, Altair RADIOSS) simulation software — together with integrated Artificial Intelligence and Machine Learning — enables manufacturers to create seats that deliver a superior driving experience for their customers.

Contact US and Discover Solutions