Multi-Phase Flows CFD Analysis

Multi-Phase Flows CFD Analysis

Multi-Phase Flows CFD Analysis

Artificial Intelligence Analysis

FEA|CFD & AI Integration

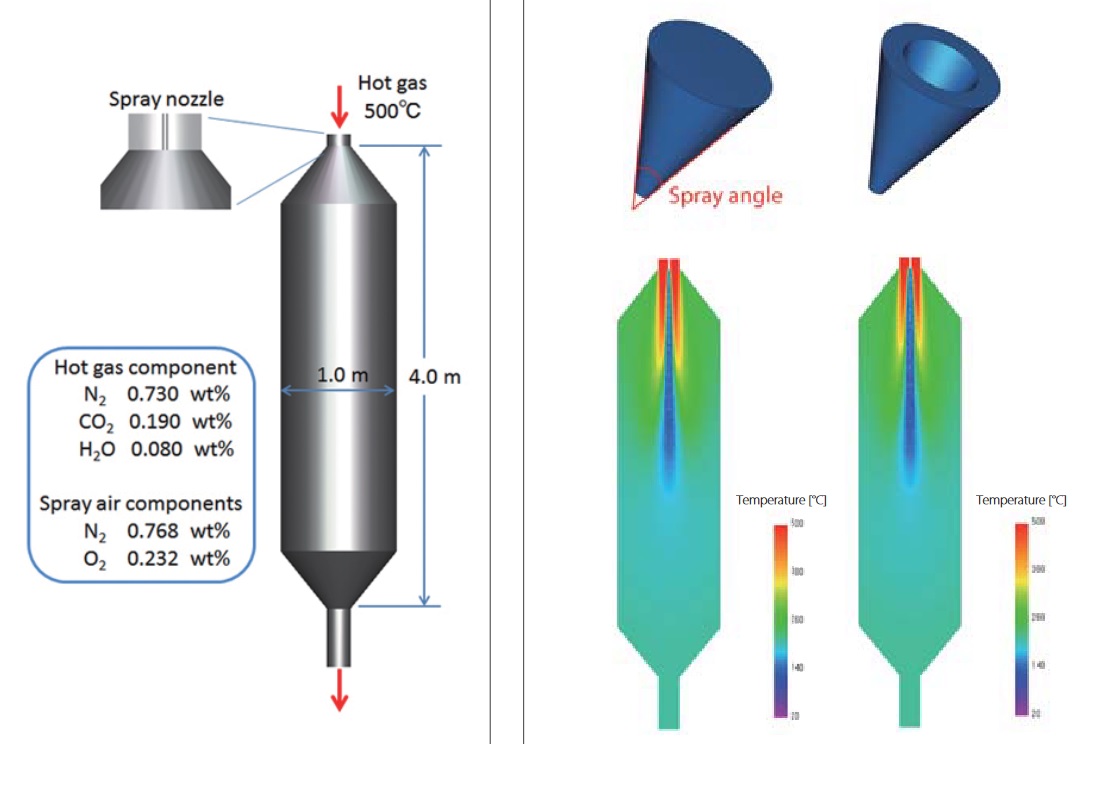

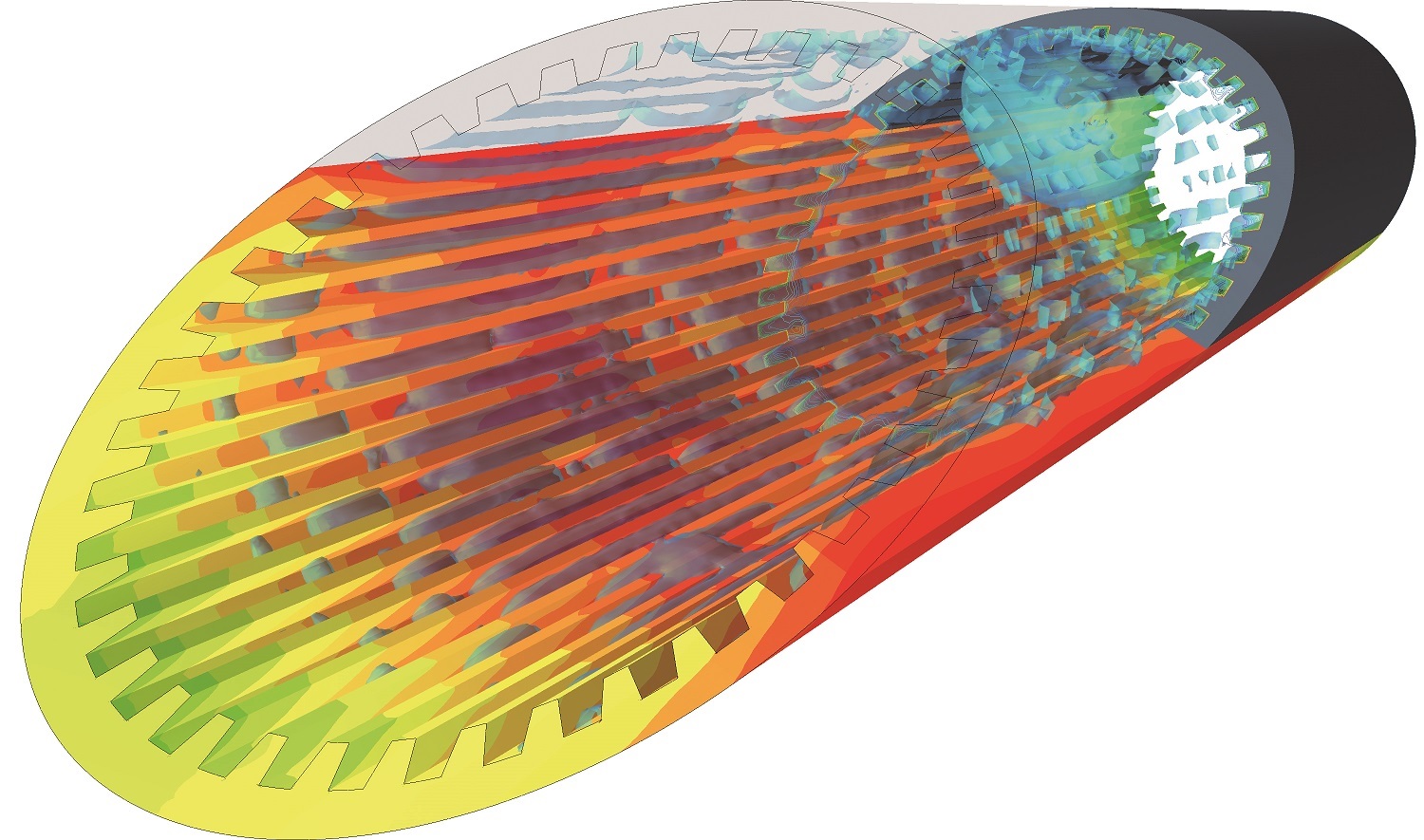

Multi-Phases flows involve combinations of solids, liquids and gases which interact. Computational Fluid Dynamics (CFD) is used to accurately predict the simultaneous interaction of more than one combination of phases that can be gases, solids or fluids. Typical applications involve sprays, solid particulate transport, boiling, cavitation, state-changes, free surface flows, dispersed multiphase flows, buoyancy problems and mixed species flows.

Contact US and Discover Solutions