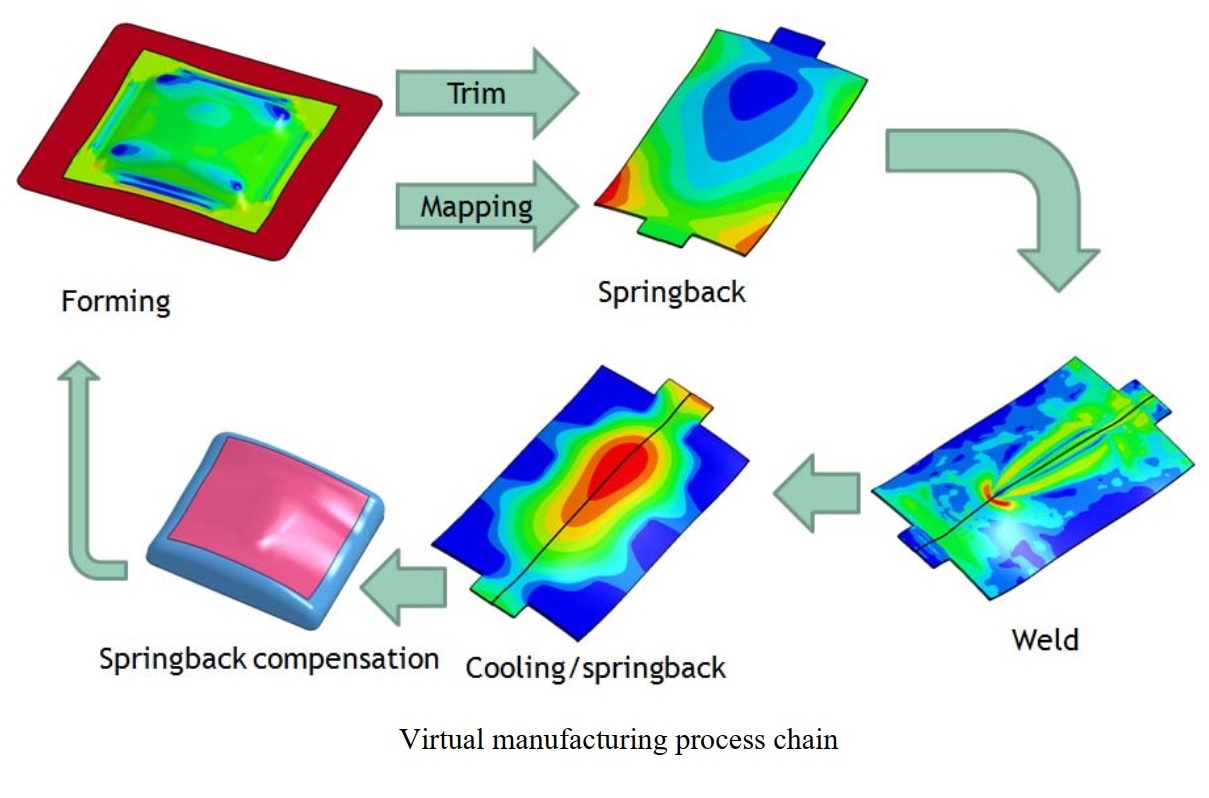

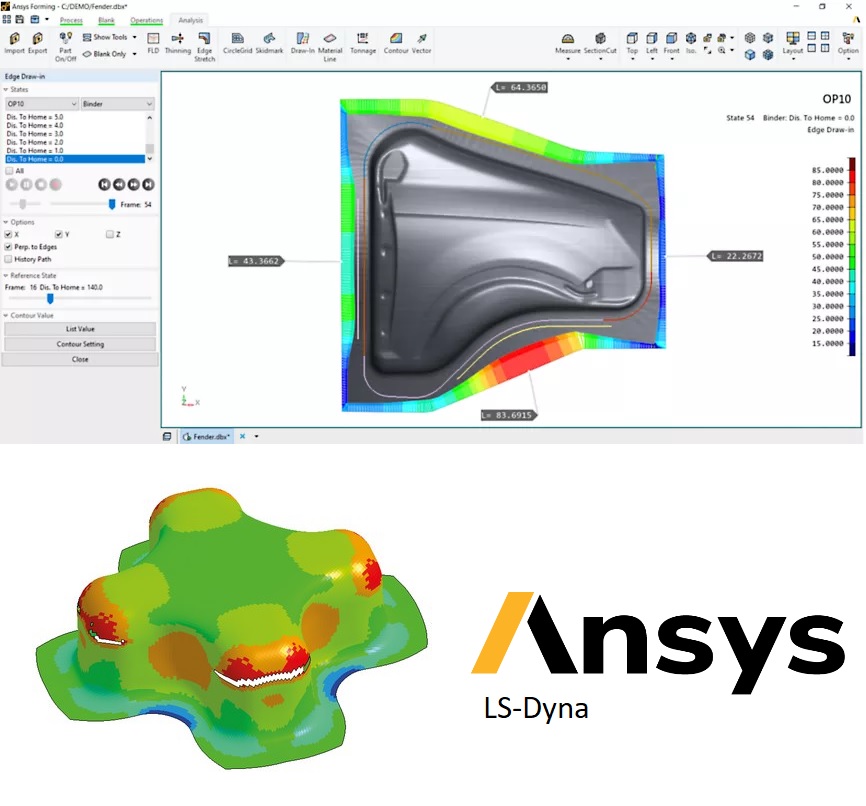

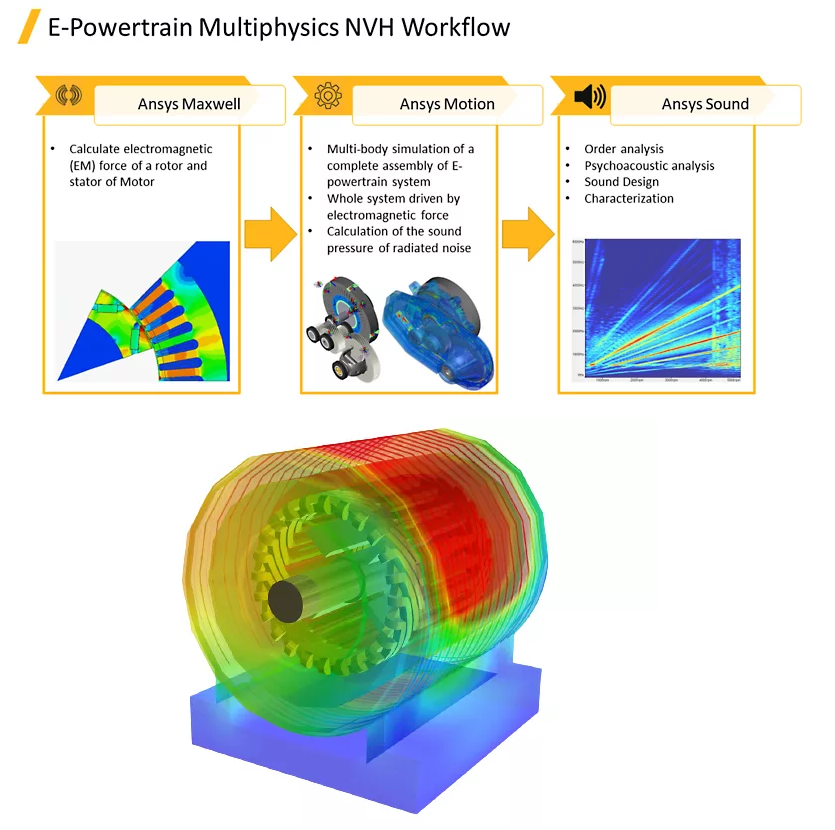

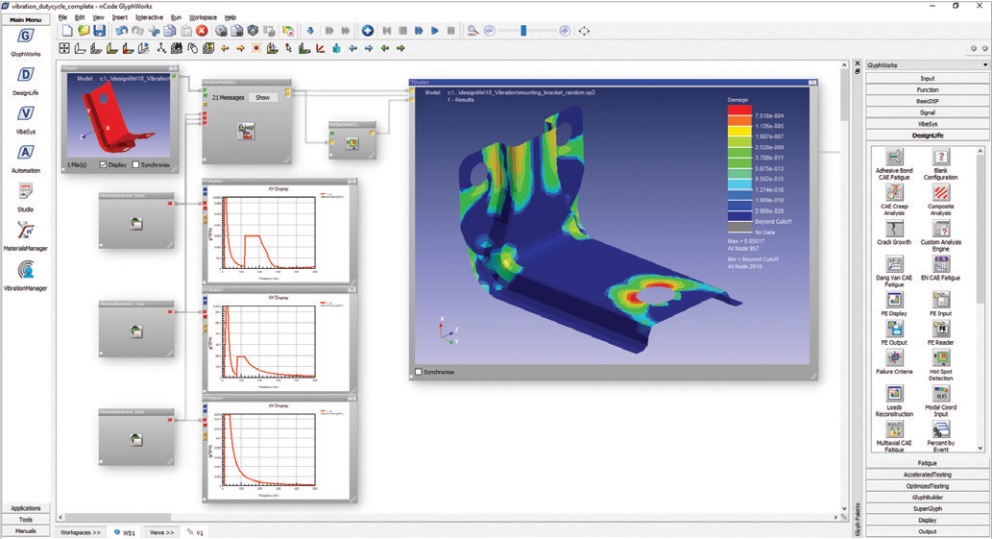

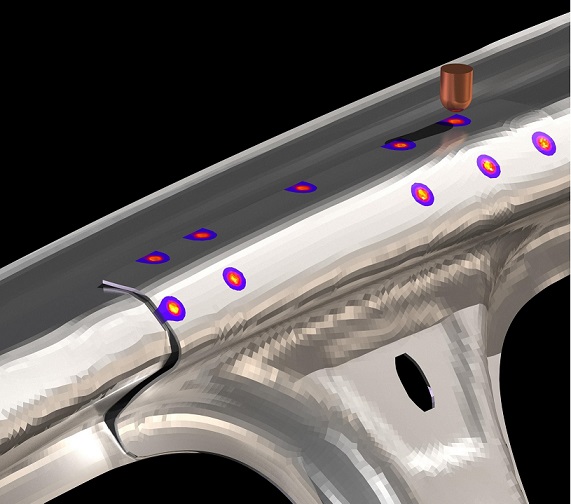

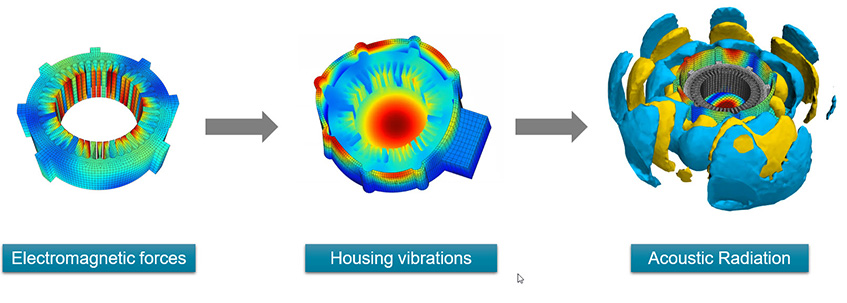

Advanced finite element analysis (FEA) tools such as Ansys, LS-Dyna and Abaqus can be used for sheet metal forming design and simulation to evaluate the feasibility of the project and predict the behavior of the material during the forming process. FEA can provide valuable insights into the material behavior, which can help engineers optimize the process parameters and reduce the risk of defects such as cracking, tearing, and wrinkling.

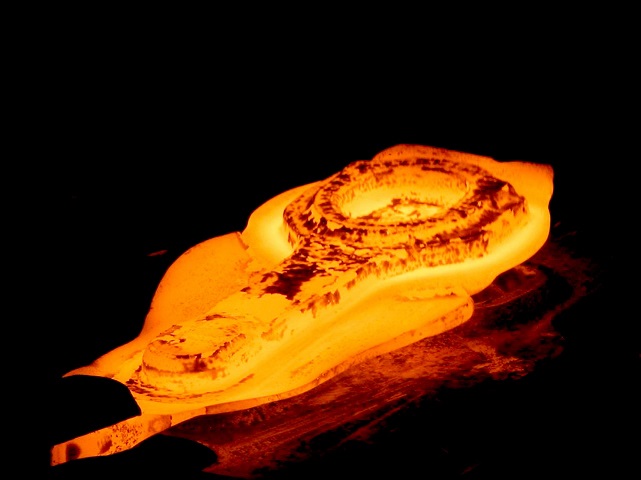

During the sheet metal forming process, the material is subjected to significant deformation and strain, which can lead to defects such as cracking or tearing. FEA can be used to simulate the entire process and predict the likelihood of these defects occurring. The simulation results can also provide information about the wall thickness distribution, edge curvature, and hardness distribution in forming steps, which are important factors to consider when designing sheet metal parts.