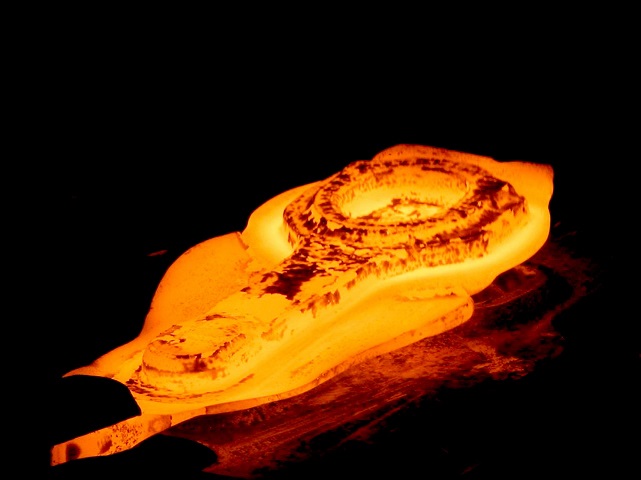

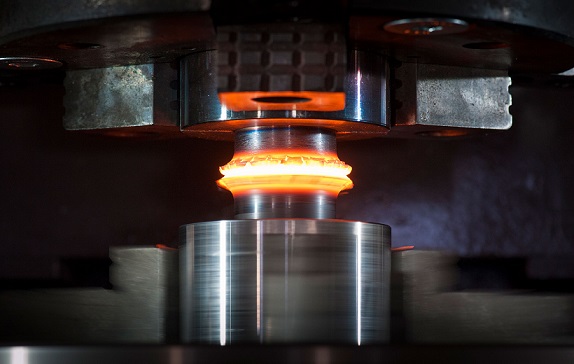

Rolling processes are used in all areas of forming technology, both in hot forging and cold forming, and of course in sheet metal forming. In a rolling process, material is deformed by applying compressive forces between two or more rollers, which reduces the thickness or changes the shape of the material. During the process, the material undergoes significant deformation and strain, which can lead to defects such as cracks, voids, and surface imperfections.

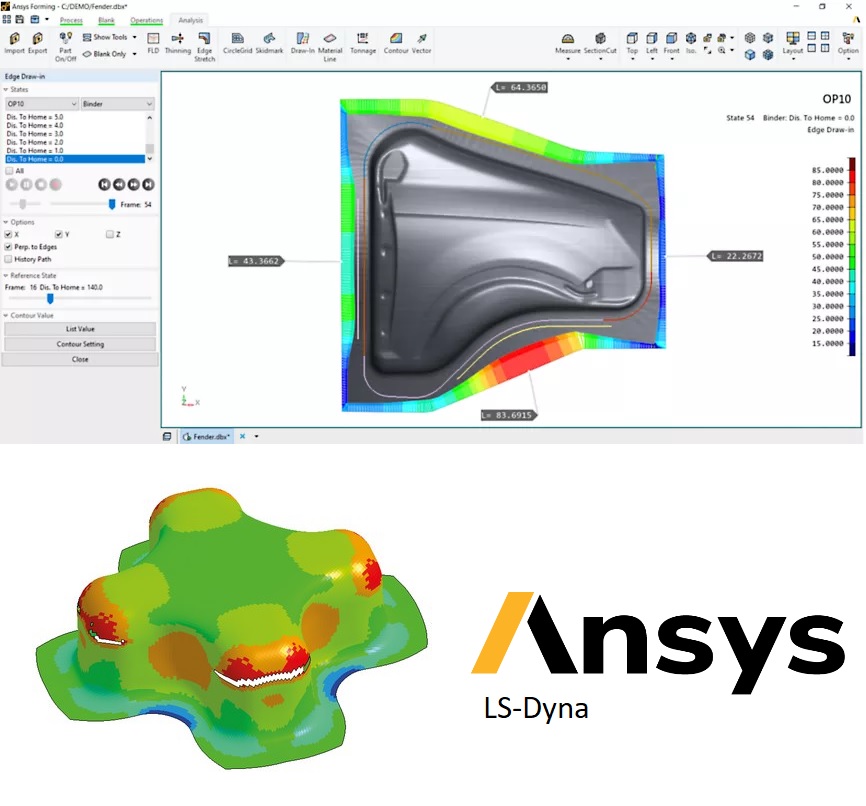

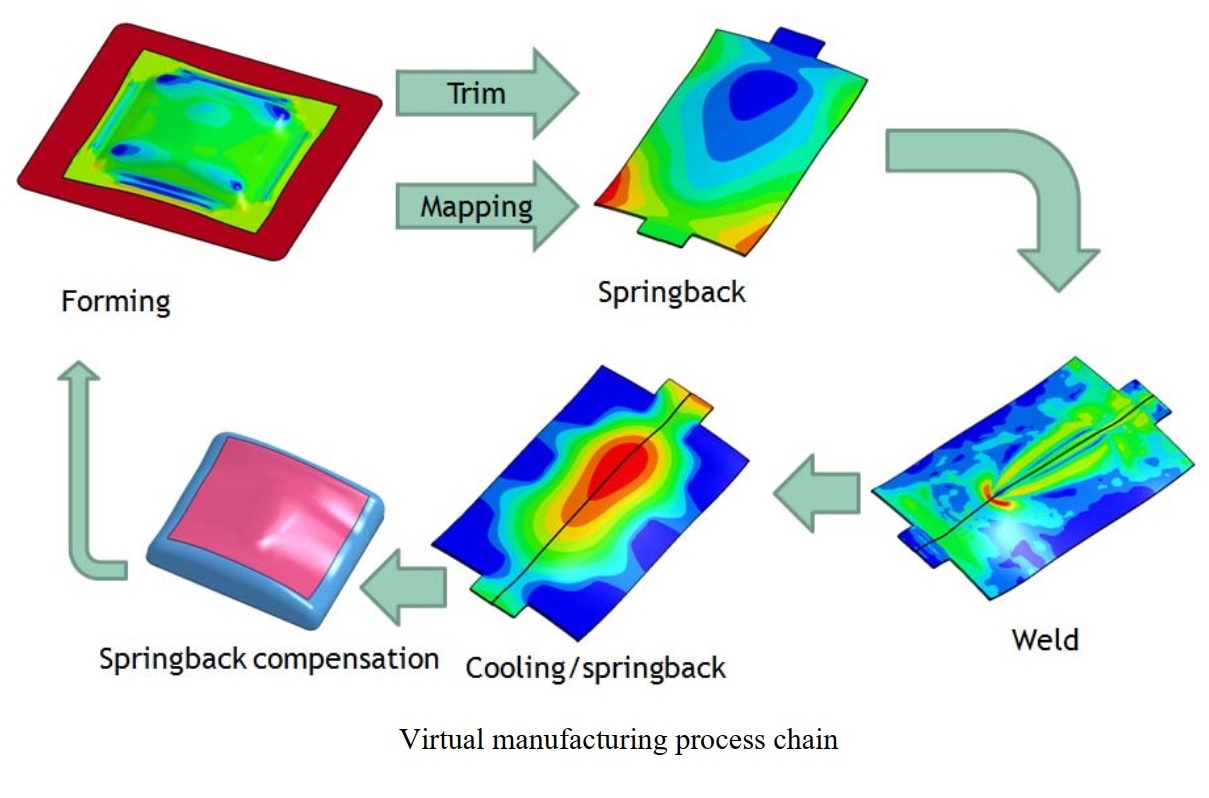

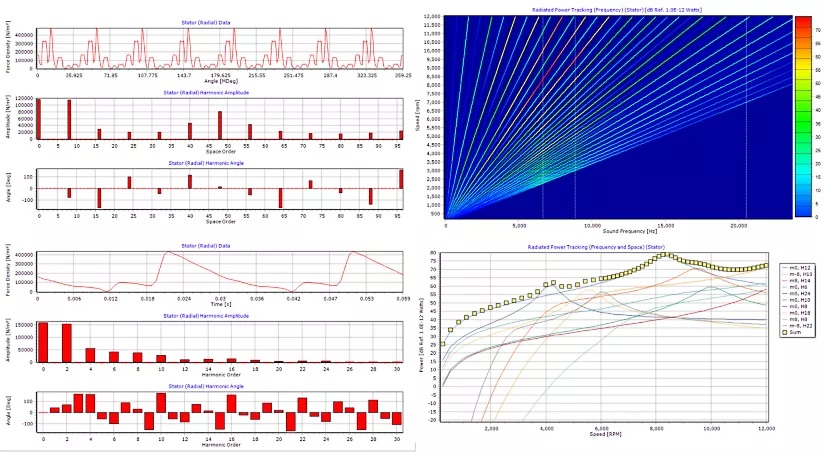

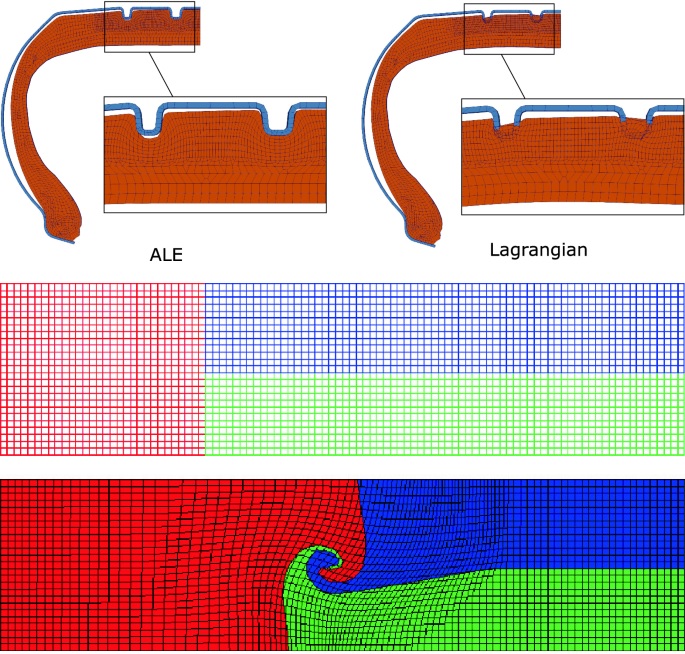

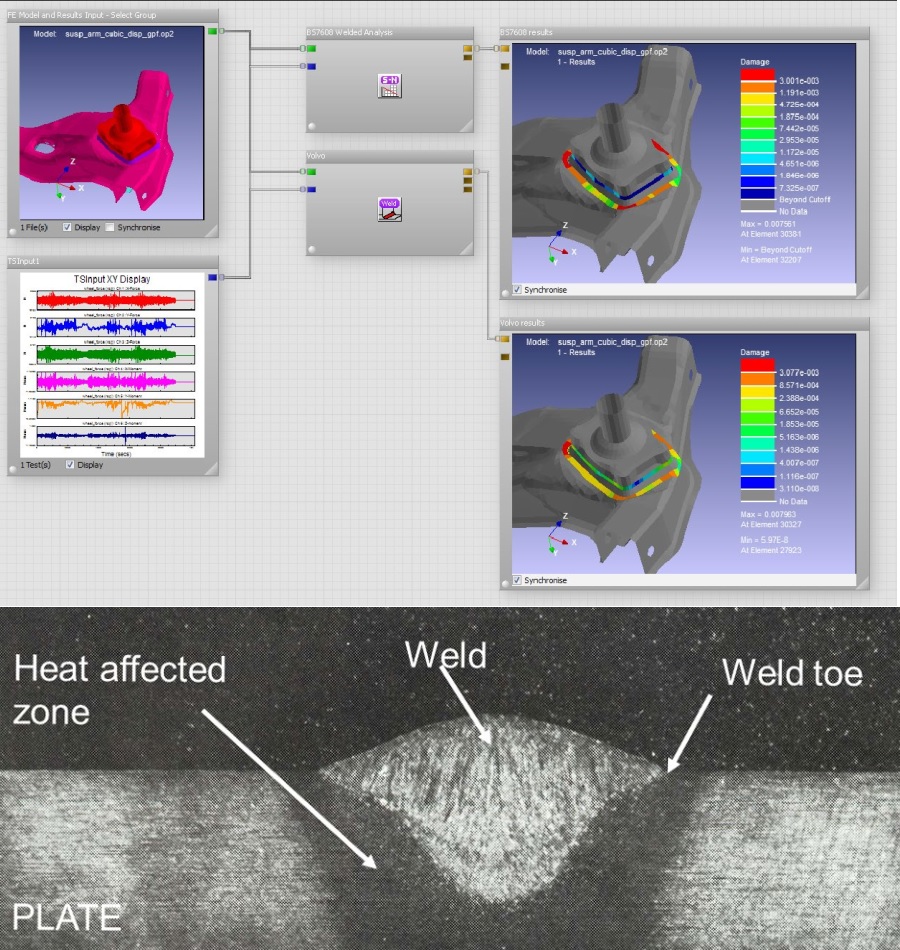

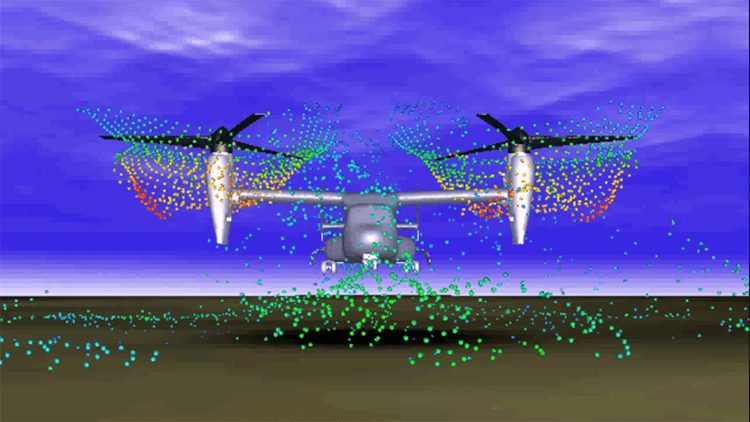

Finite element simulation be used to model the rolling process and predict the behavior of the material during forming, including the formation of defects. By adjusting the process parameters such as temperature, pressure, and forming time, engineers can optimize the process to produce high-quality parts with the desired mechanical properties.

Simulation also be used to analyze the effect of different rolling techniques, roller geometries, and lubrication on the final product. This can help engineers to design and develop new rolling processes that are more efficient, cost-effective, and produce higher quality parts.