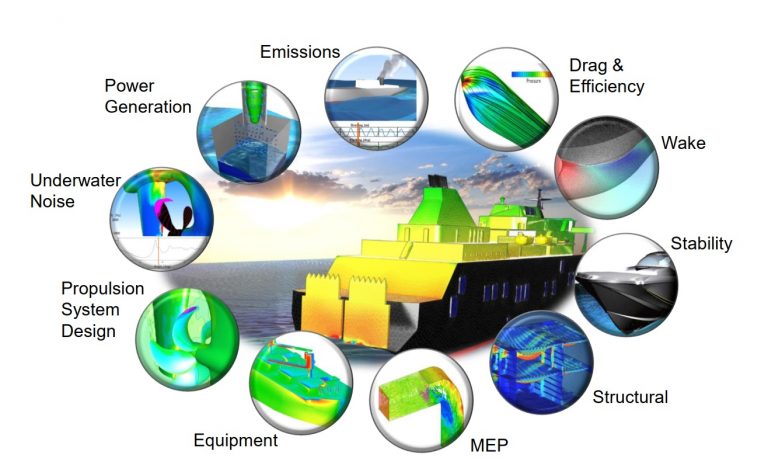

The hull design can significantly impact a vessel's speed, stability, fuel consumption, and overall operating costs. Traditionally, vessels have been optimized for a single operating condition, such as the contract speed at design draft. However, with the help of advanced computational fluid dynamics (CFD) tools and modern computers, it is now possible to optimize a vessel's hull design for a range of operating conditions.

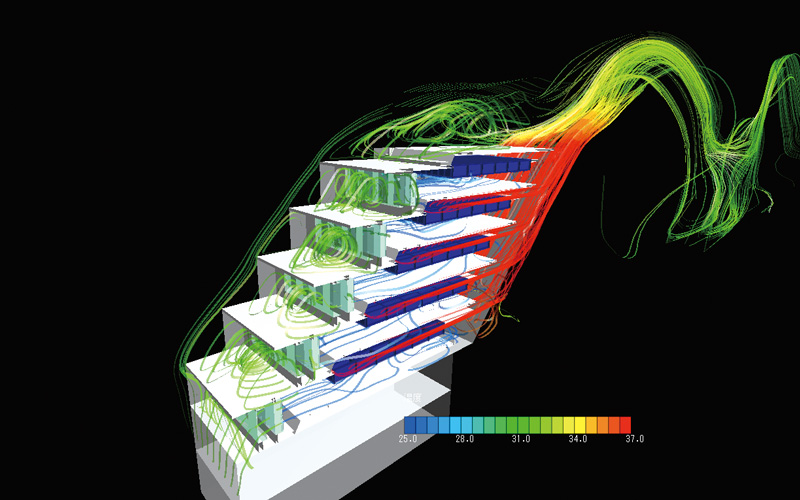

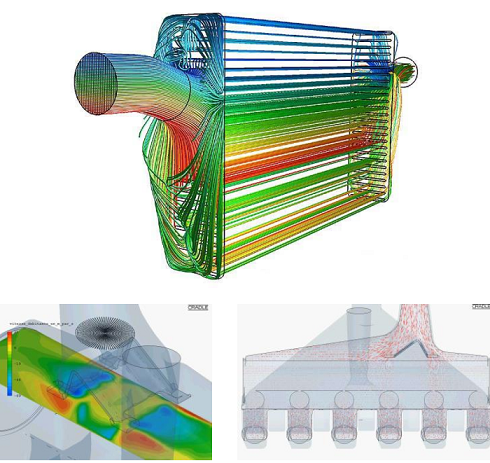

CFD allows engineers to model and simulate the flow of water around the hull of a vessel under different conditions, such as varying vessel speeds, drafts, and trims. By analyzing the results of these simulations, engineers can identify areas of the hull design that may be causing drag or turbulence, and make modifications to improve the overall hydrodynamic performance.

By optimizing the hull design for lower resistance at slow speeds, vessels can achieve greater fuel efficiency when operating in port or in calm waters. Conversely, optimizing for higher speeds can improve a vessel's performance in open seas or in rough weather conditions.

In addition to optimizing the hull design for different operating conditions, CFD can also be used to analyze the impact of different design features, such as bulbous bows or stern flaps, on the vessel's hydrodynamic performance.