Model-Based Systems Engineering (MBSE) is a methodology that utilizes models to describe and analyze complex systems, including their components, behaviors, interactions, and requirements, throughout their lifecycle. The use of models enables a better understanding of the system and its characteristics, facilitates communication and collaboration among stakeholders, and supports the verification, validation, and optimization of the system design.

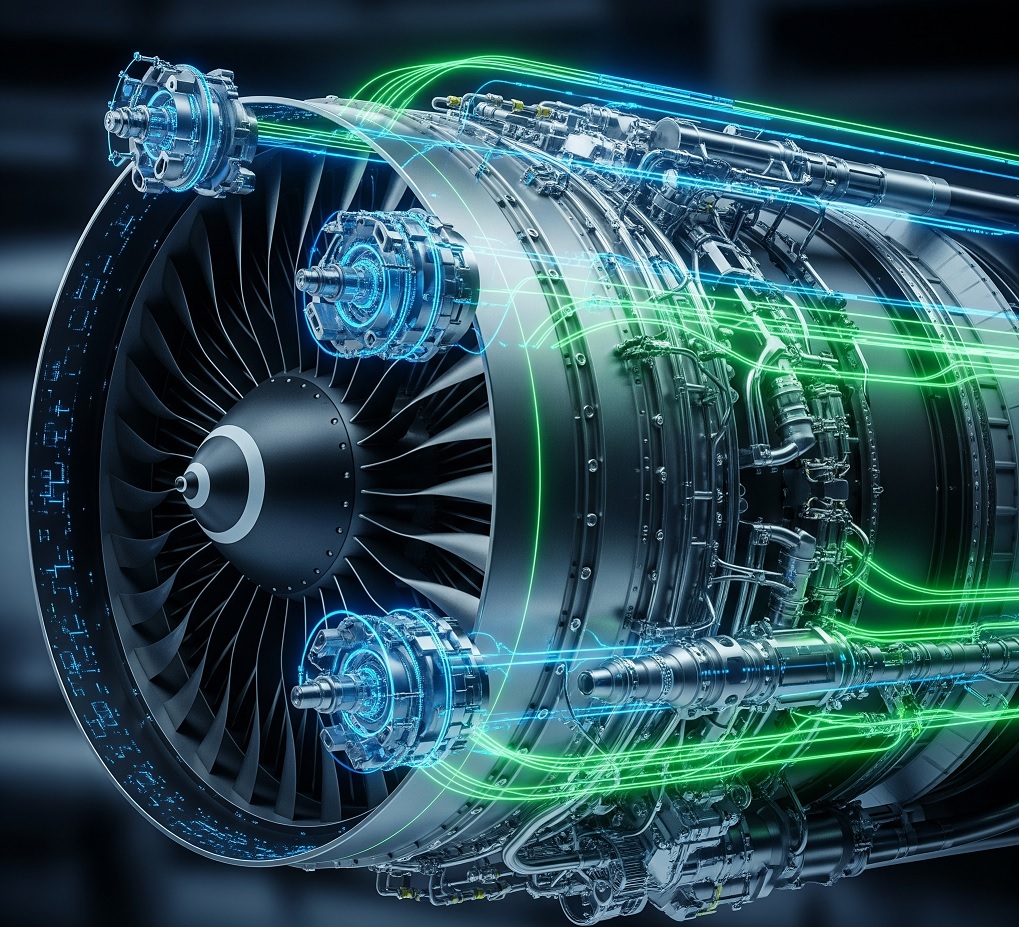

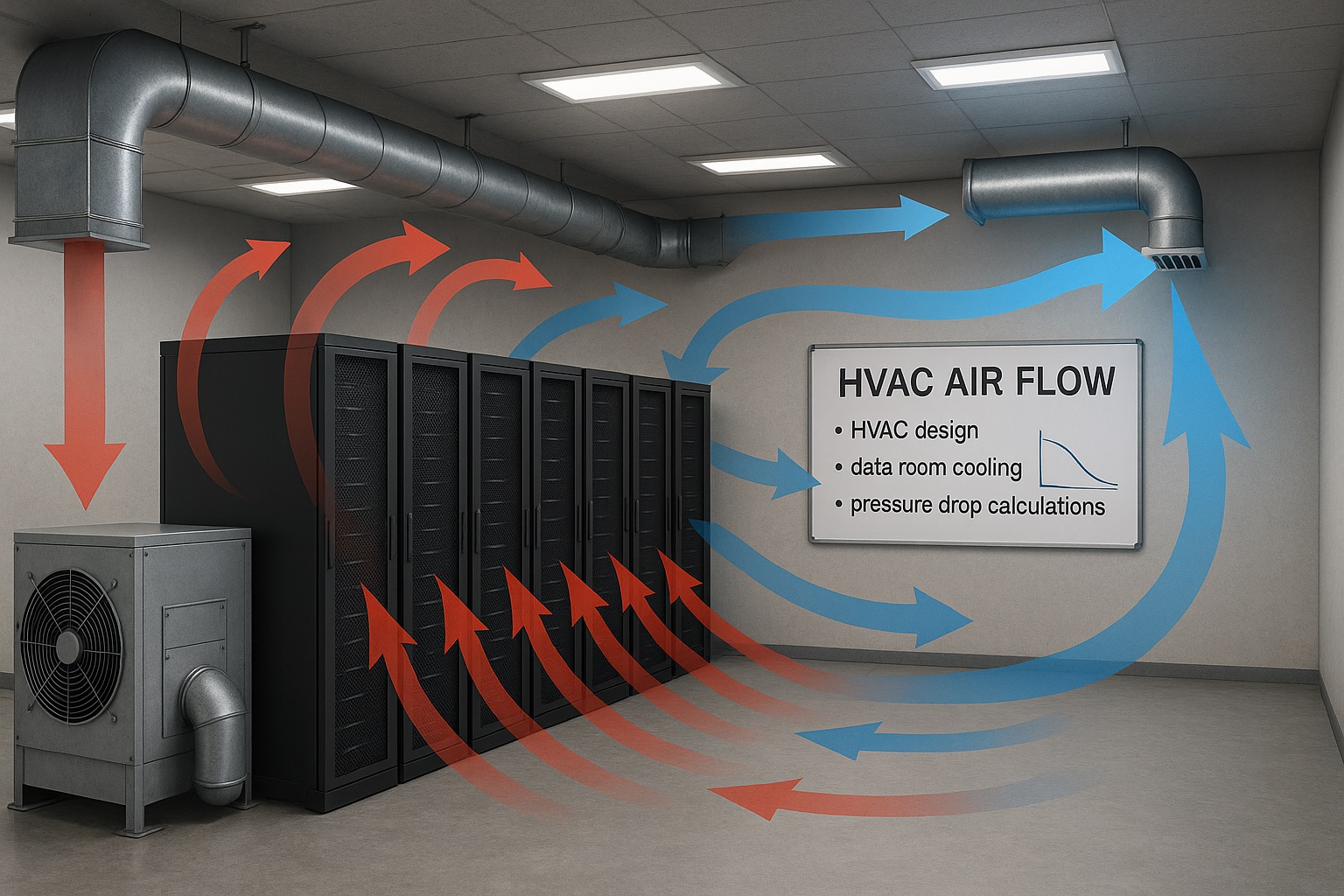

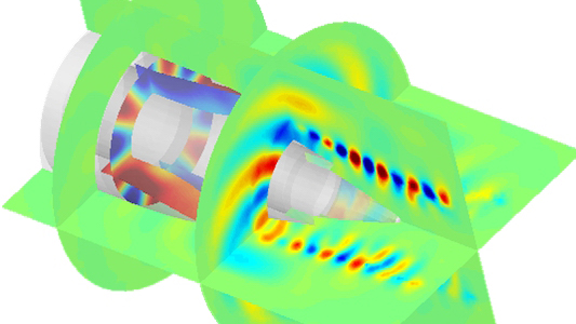

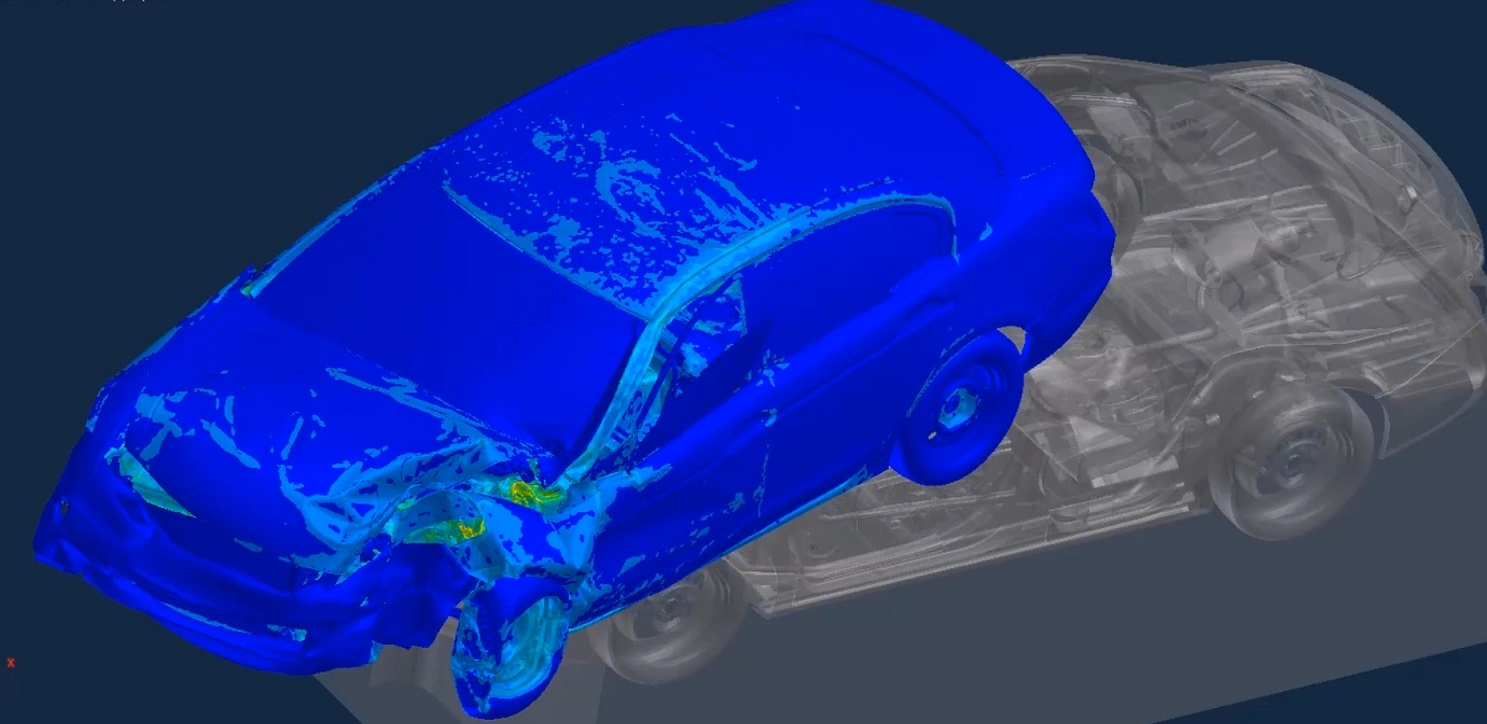

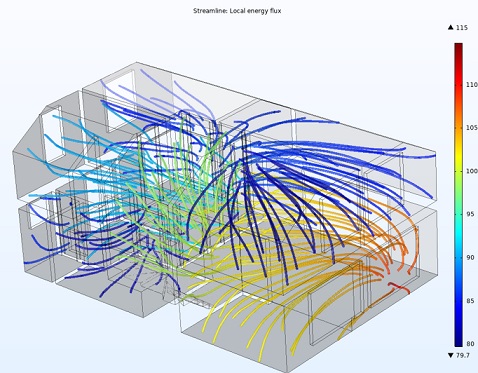

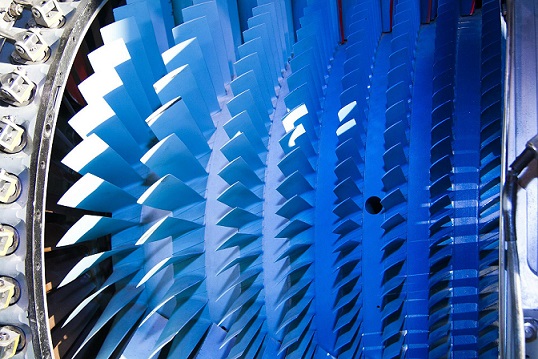

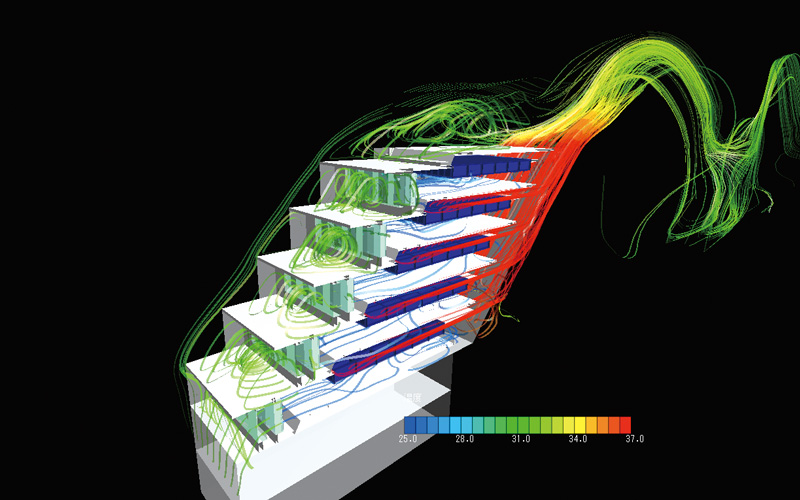

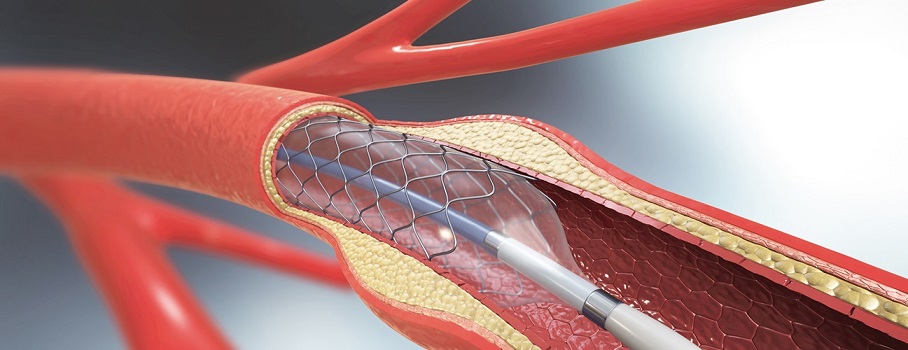

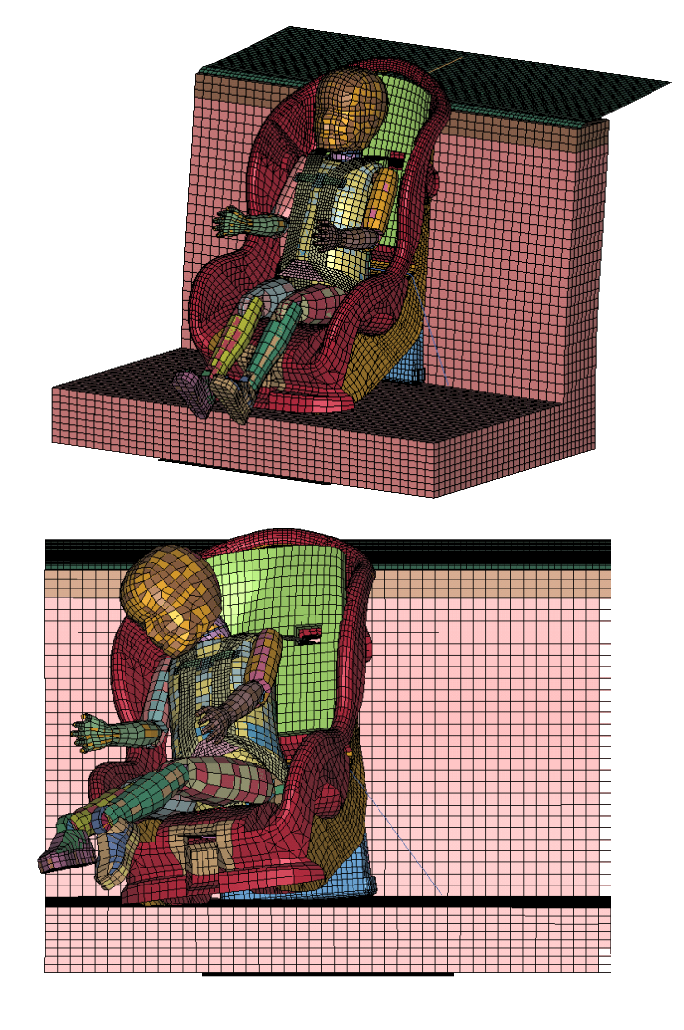

CAE (Computer-Aided Engineering) systems simulation is a process that utilizes computer software to simulate the behavior and performance of physical systems and their components, based on mathematical models and numerical methods. CAE can be used to analyze and optimize the design of products, processes, and systems, in various domains such as aerospace, automotive, energy, manufacturing, and healthcare.

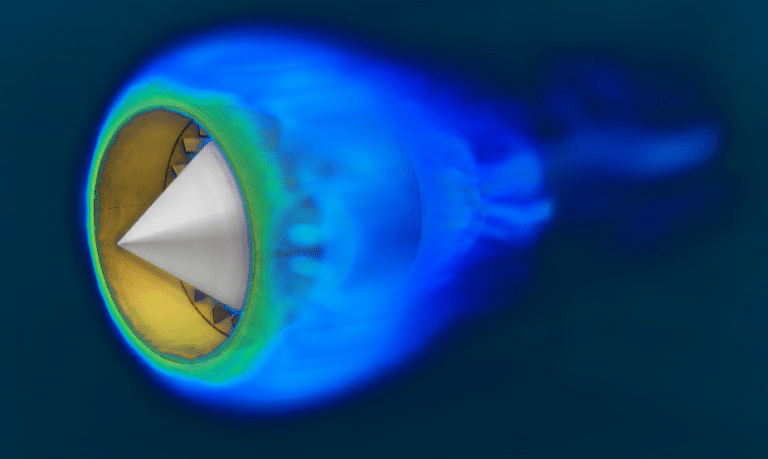

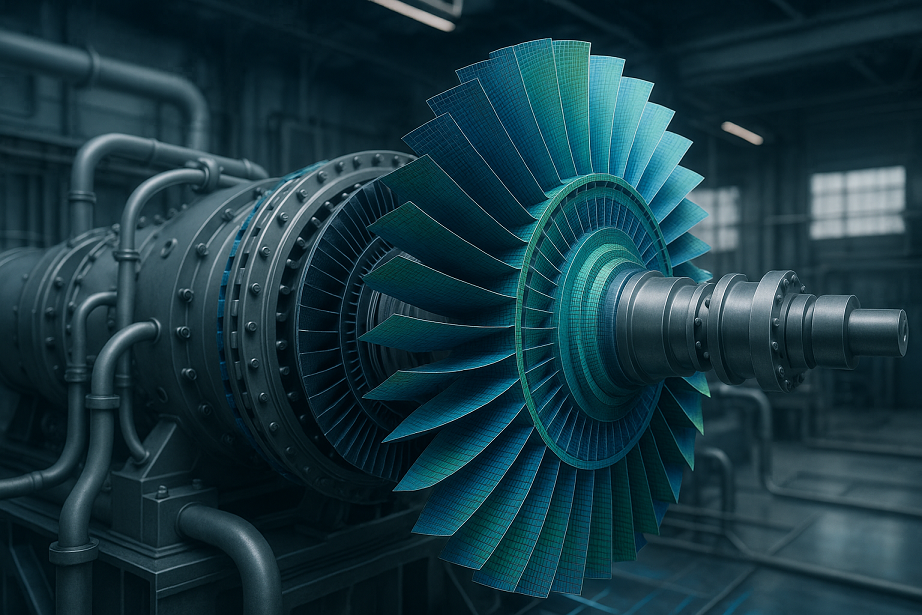

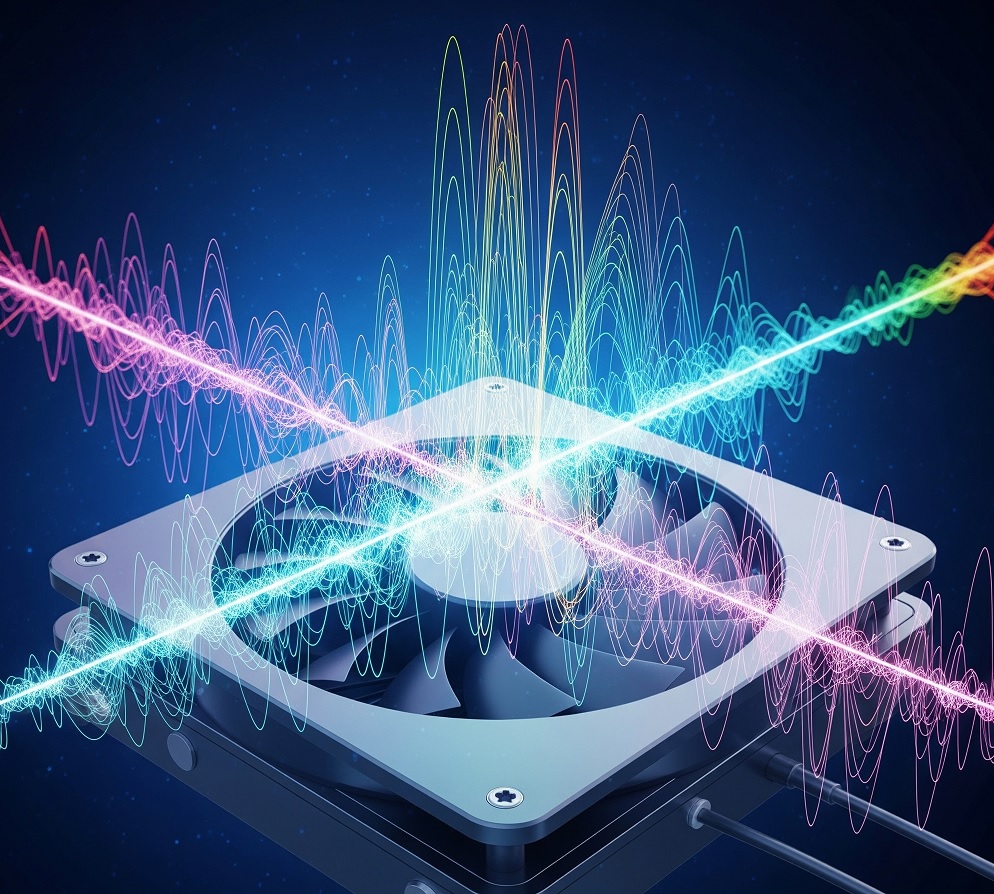

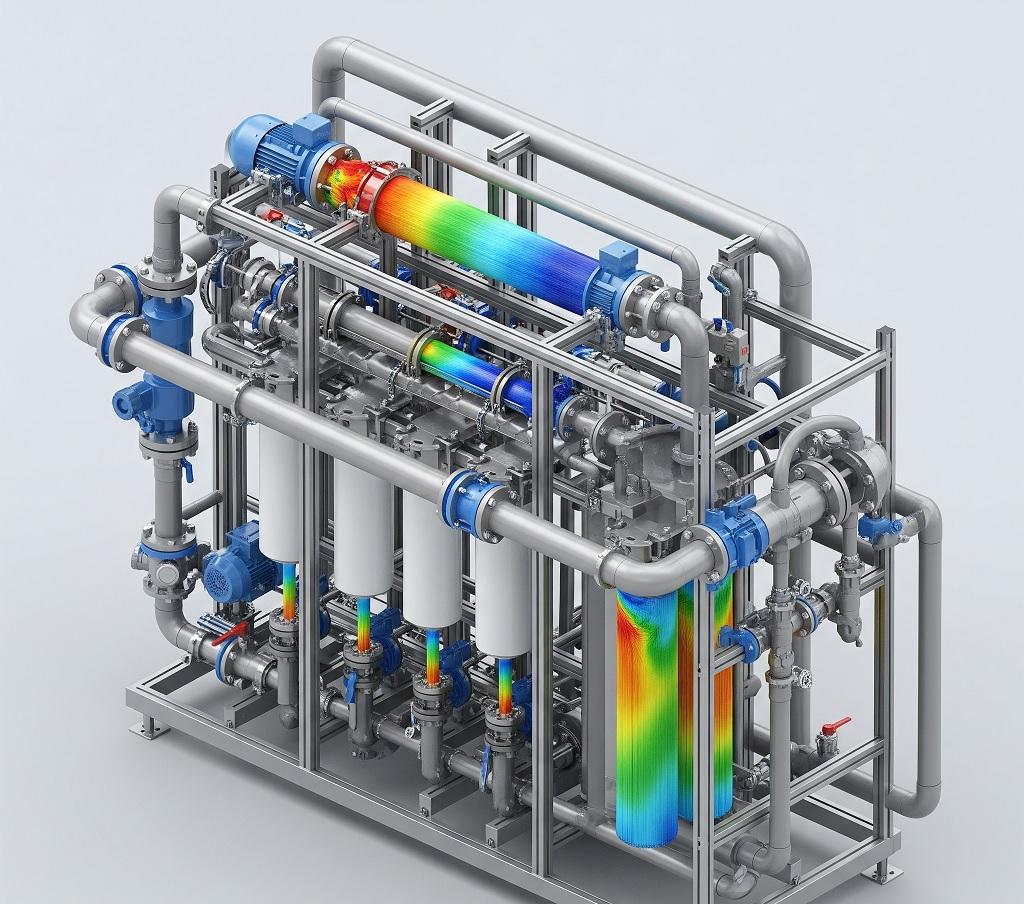

The use of a comprehensive set of software with 0D/1D/3D multi-physics component libraries, allows for the simulation of the physics of fluid flow, thermal, mechanical, multi-body, structural, electrical, magnetic, chemistry, and controls, which are essential for many industrial applications. The integrated multi-physics capabilities enable the modeling of complex systems, where the interactions between different physical domains are important, such as in the case of pumps, compressors, oil and gas piping systems, chemical processing plants, and other stationary machinery.

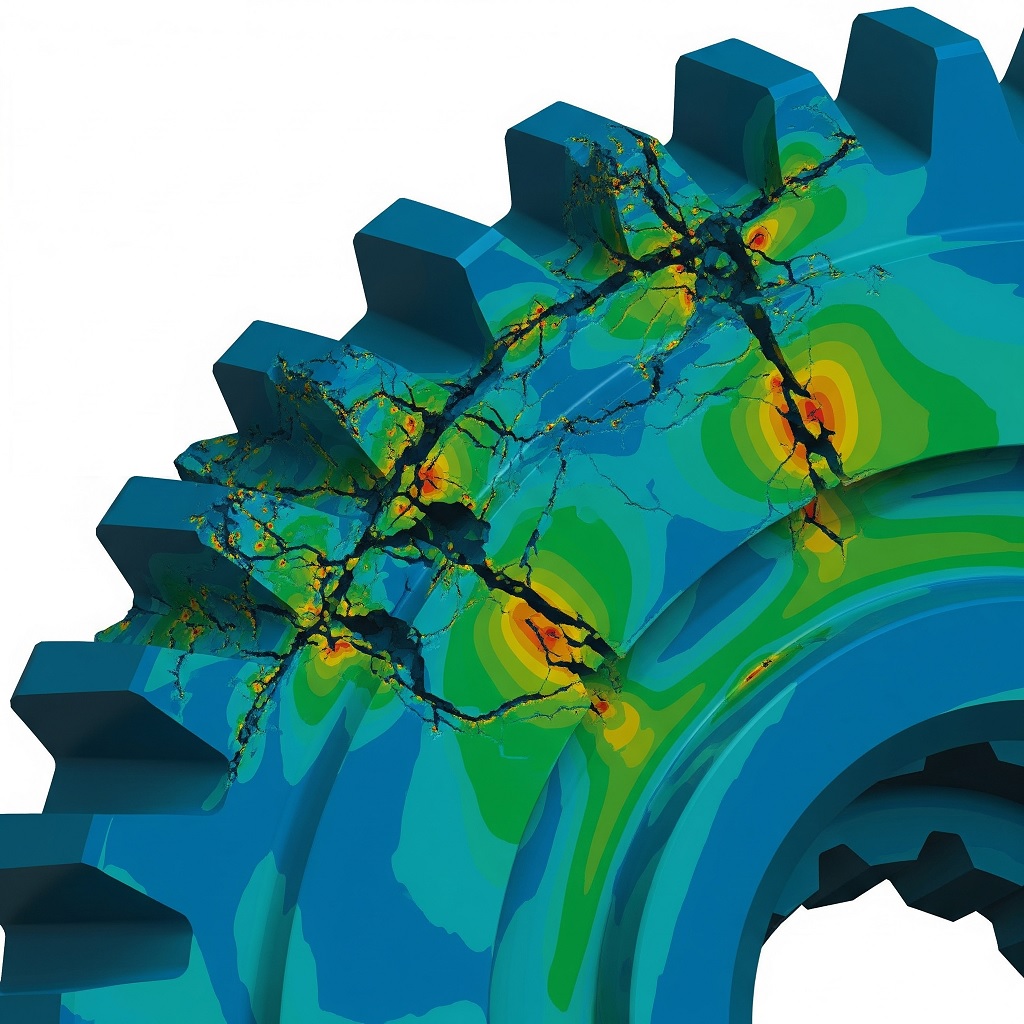

The system simulation tool by our engineers uses 0D/1D models for components, which are strengthened by the capability to perform full 3D analysis (CAD, FEA, CFD) for needed components. This approach allows for the simulation of both the overall system behavior and the detailed performance of specific components, based on the available data and requirements. This flexibility and scalability are essential for the design, analysis, and optimization of complex systems.

The use of DOE (Design of Experiments) and optimization techniques, help us to obtain the best design Pareto, which represents the optimal trade-off between different design criteria and constraints. This approach allows for the exploration of the design space, the identification of the most influential factors, and the selection of the best design alternatives, based on the desired objectives and constraints.