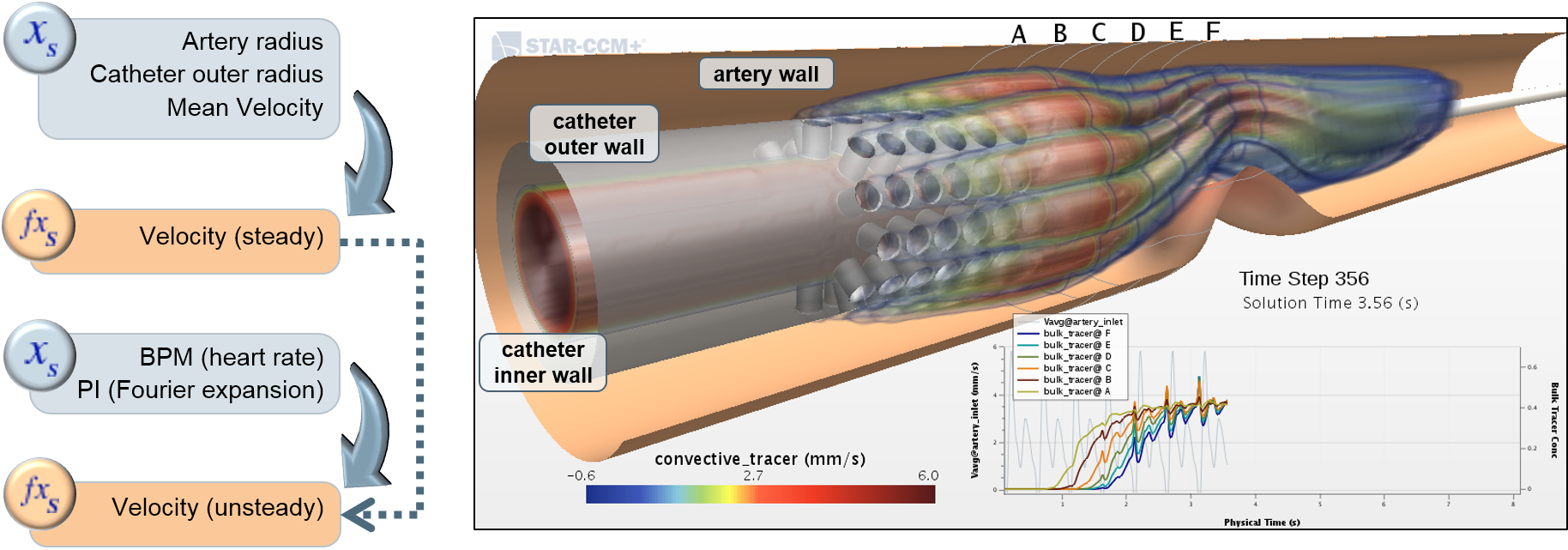

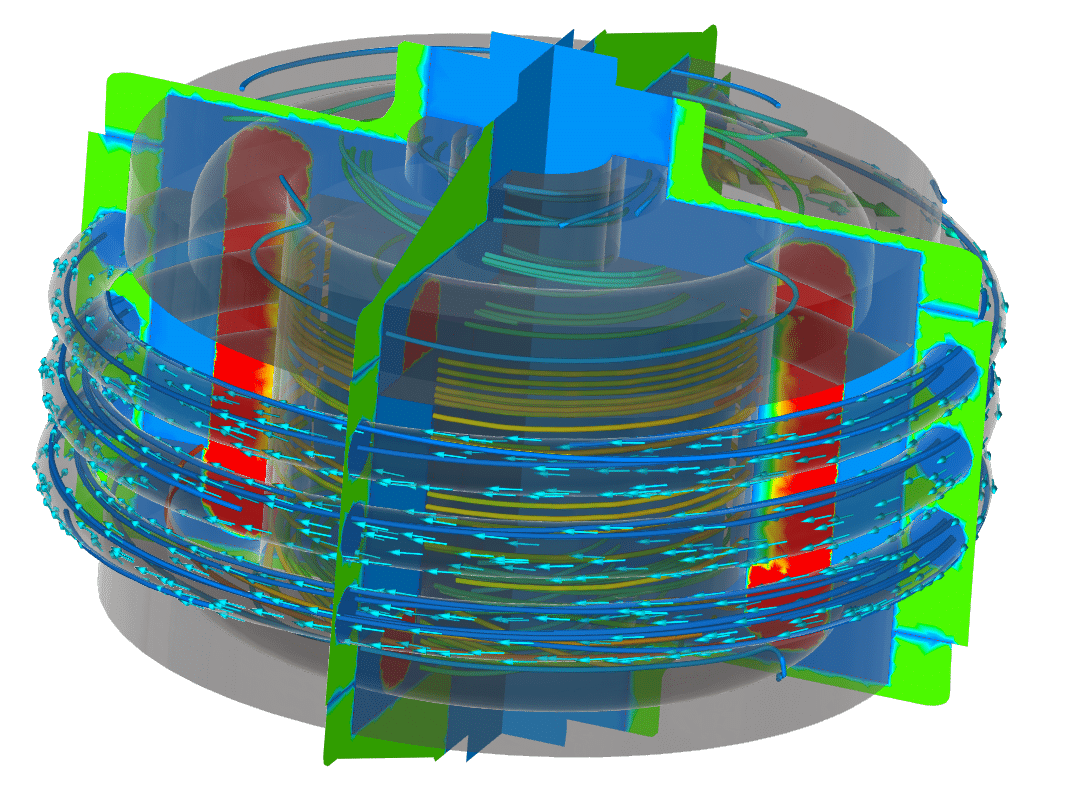

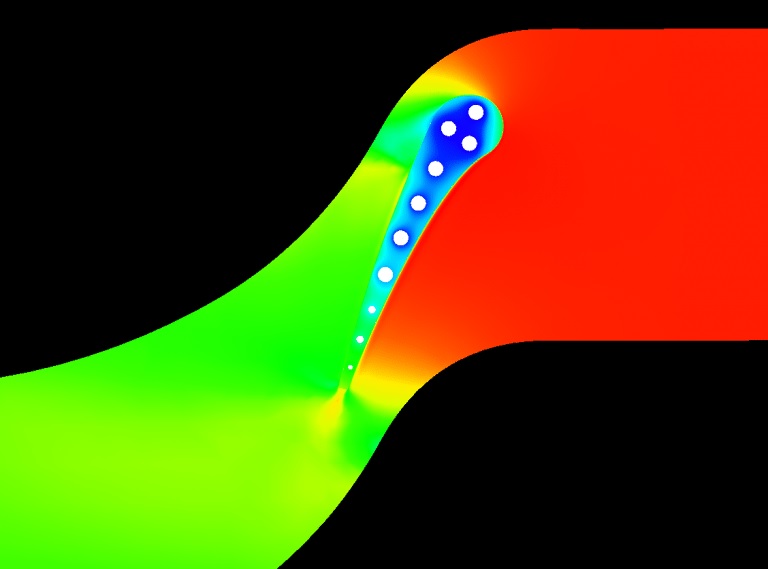

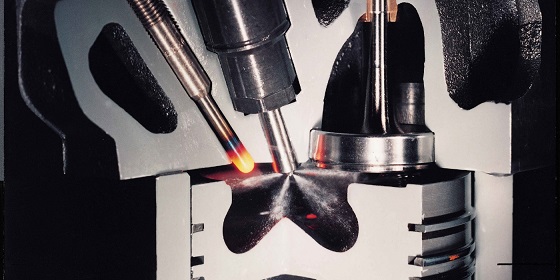

Applications such as leakage paths and thin film flows where thermal-stress induced structural deformation affects fluid flow present an even more difficult simulation challenge.

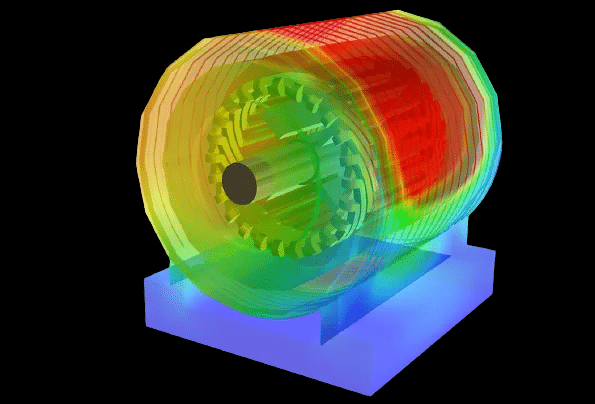

These applications can be simulated with two-way coupled CFD and structural thermal simulation. With this approach, the fluid flow solution is applied to the structure and the deformation of the structure is in turn applied to the fluid flow at each time step of the simulation. Two-way CFD and structural thermal simulation made it possible to set up a transient simulation that simultaneously solves the heat transfer coefficients (HTC) and near-wall temperatures in the fluid.

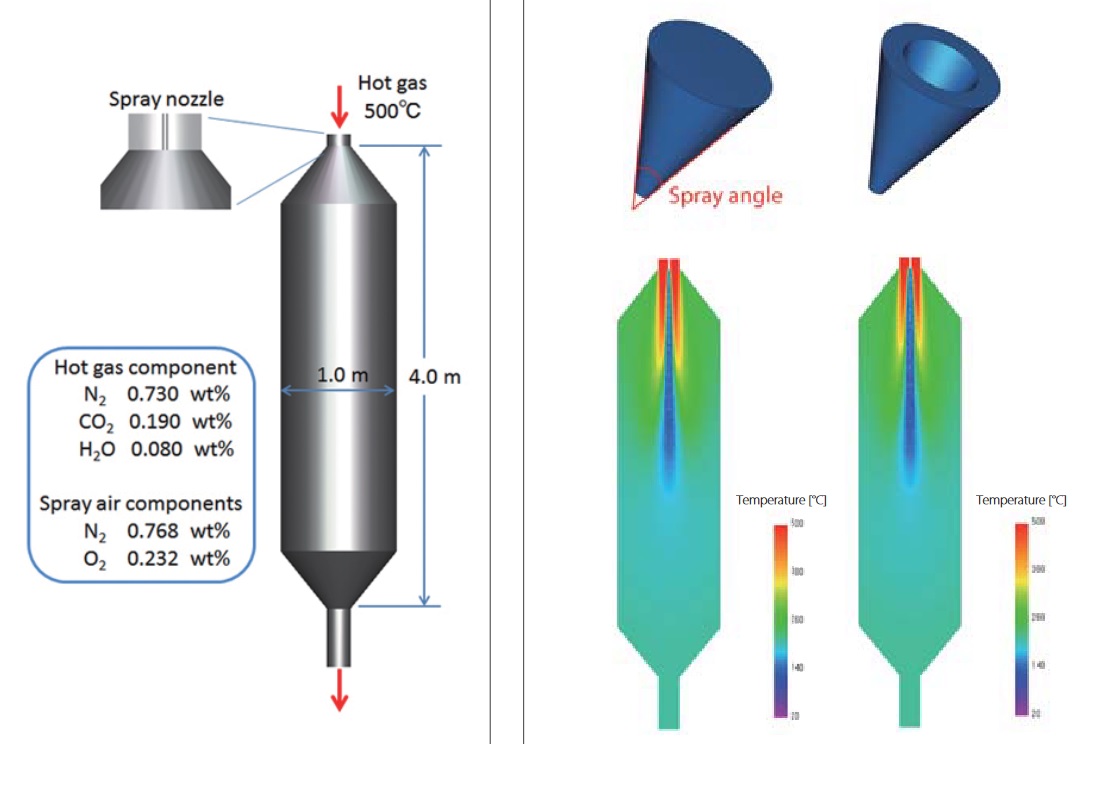

Failure to properly manage thermal performance can lead to inefficient energy use, uncomfortable or even unsafe temperatures, suboptimal performance and lower than expected product life. Engineering simulation is essential to diagnosing and evaluating solutions for thermal problems early in the design process when they can be corrected at the least possible cost and time. Simulation Dynamics’s engineering team can accurately predict thermal performance across a wide range of operating conditions with deep knowledge in FEA and CFD; coupling them gives us the capabilities required to address the most difficult thermal design challenges:

-

▶

Thermal shock resistance for brittle materials immersed in a fluid.

-

▶

Cracking mechanism in materials subject to high temperature gradients

-

▶

Furnace or burner failures

-

▶

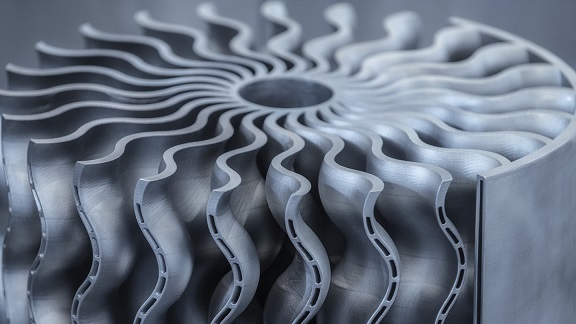

Radiators and heat exchanger flow balance

-

▶

Cross flow heat exchanger liquid gas

-

▶

Pins and turbolators pressure drop and trade-offs

-

▶

Kilns transient analysis

-

▶

Thermal shocks on solar panels

-

▶

Cooling jackets — cooling holes position and dimensions

-

▶

Automotive exhaust, turbogas exhaust

-

▶

Defrosting ducts for automotive and home appliances

-

▶

Lamps, automotive headlights