-

Industries

- Aerospace & Defense

- Automotive Engineering

- Chemical Processing

- Civil Engineering

- Energy & Power Industry

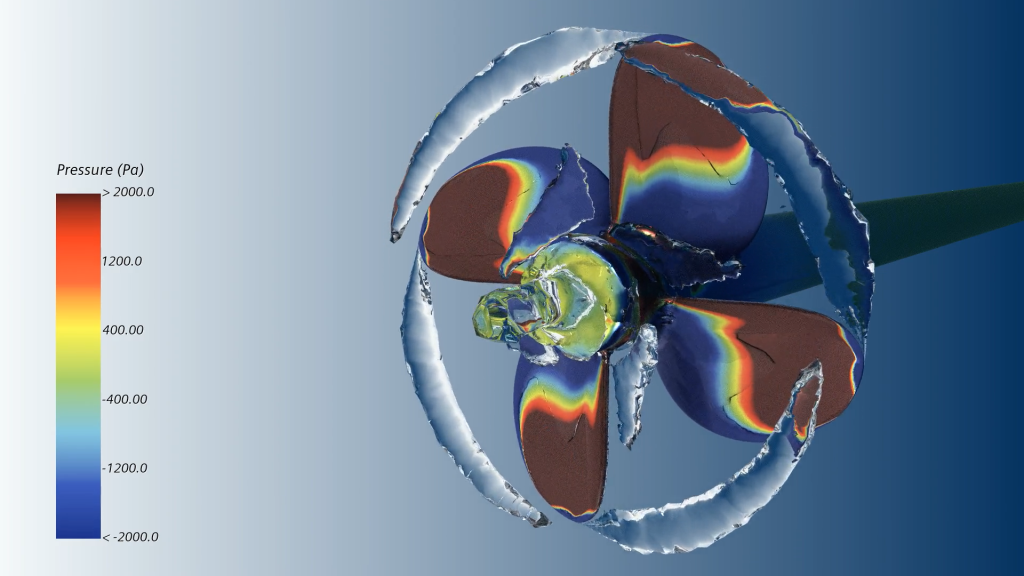

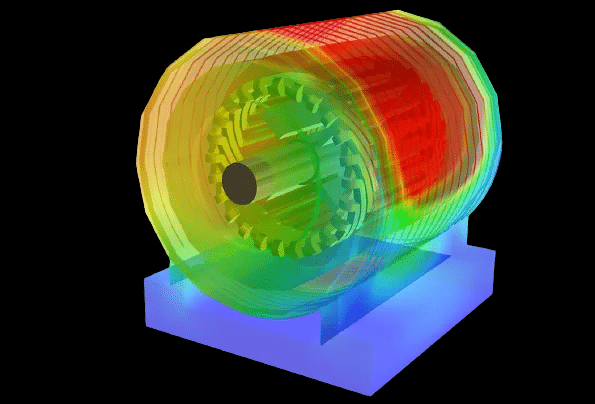

- Industrial Equipment & Rotating Machinery

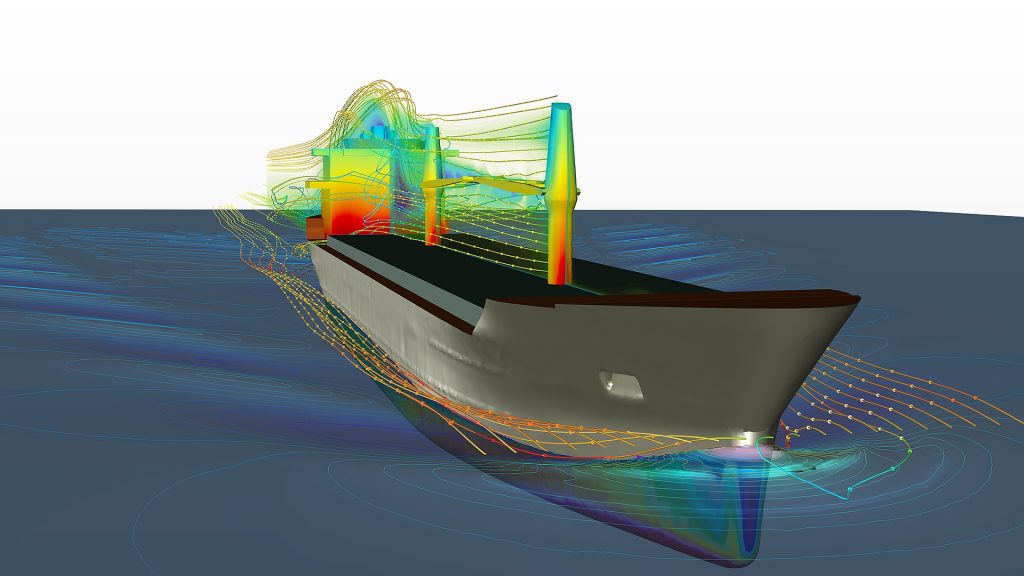

- Marine & Shipbuilding

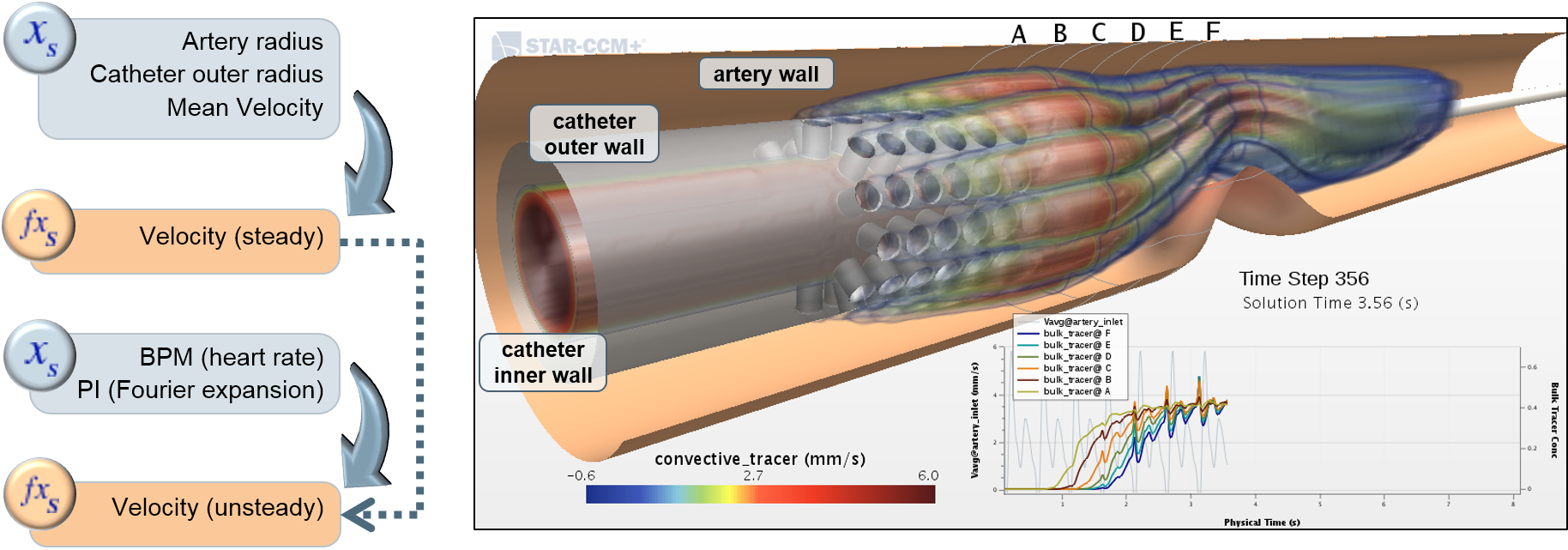

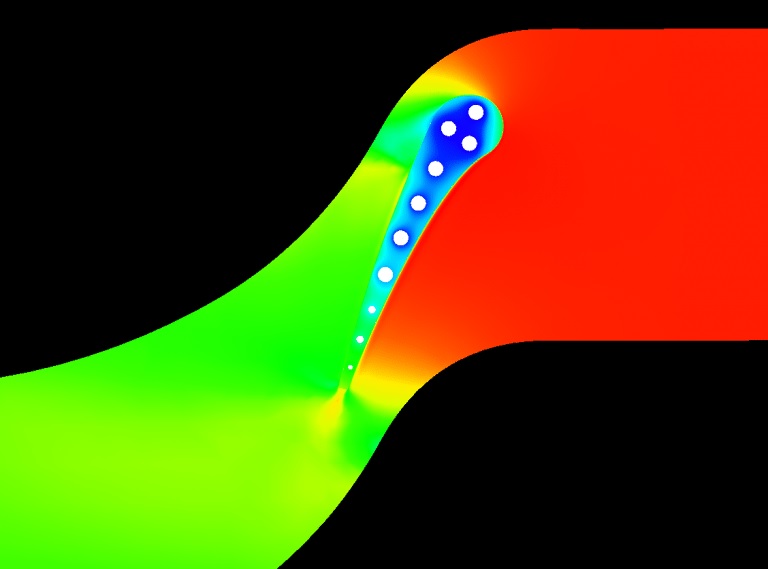

- Medical & Biomedical Devices

- Seat Design

- Artificial Intelligence

-

Finite Element

- Acoustics and Vibration

- Additive Manufacturing

- Blast, Explosion & Fire

- Composite Materials

- Crash Test Simulation

- Durability & Fatigue Life

- Metal Forming Simulation

- Multibody Dynamics

- Thermal Analysis

- VTOL, eVTOL & UAM

- Welding Simulation

-

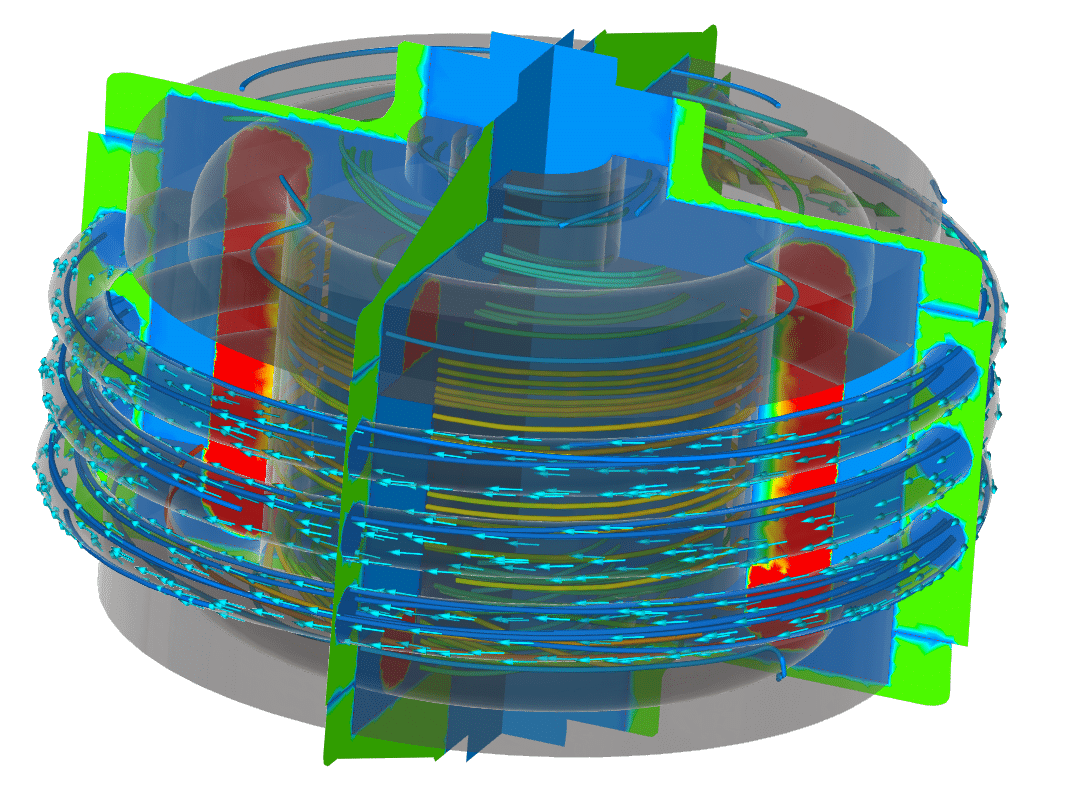

CFD

- Aerodynamics Simulation

- Fluid Structure Interaction (FSI)

- Hydrodynamics CFD simulation

- Multi-Phase Flows CFD Analysis

- MultiObjective Design of Turbomachinery

- Reacting Flows & Combustion

- Electromagnetics

- Services