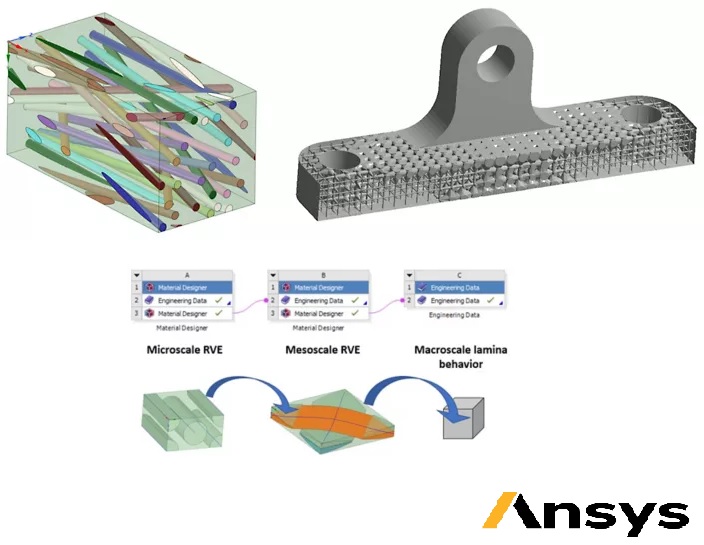

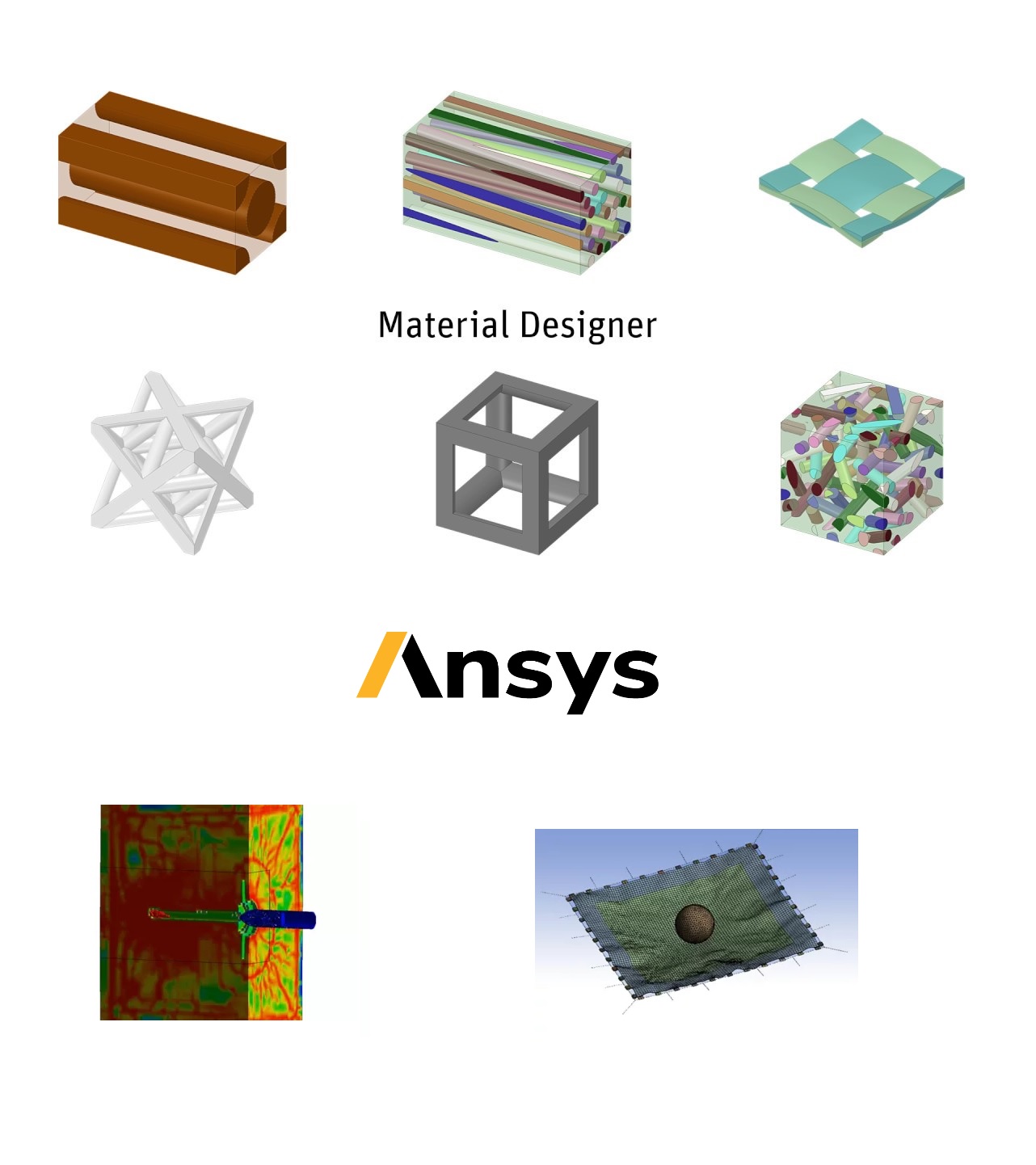

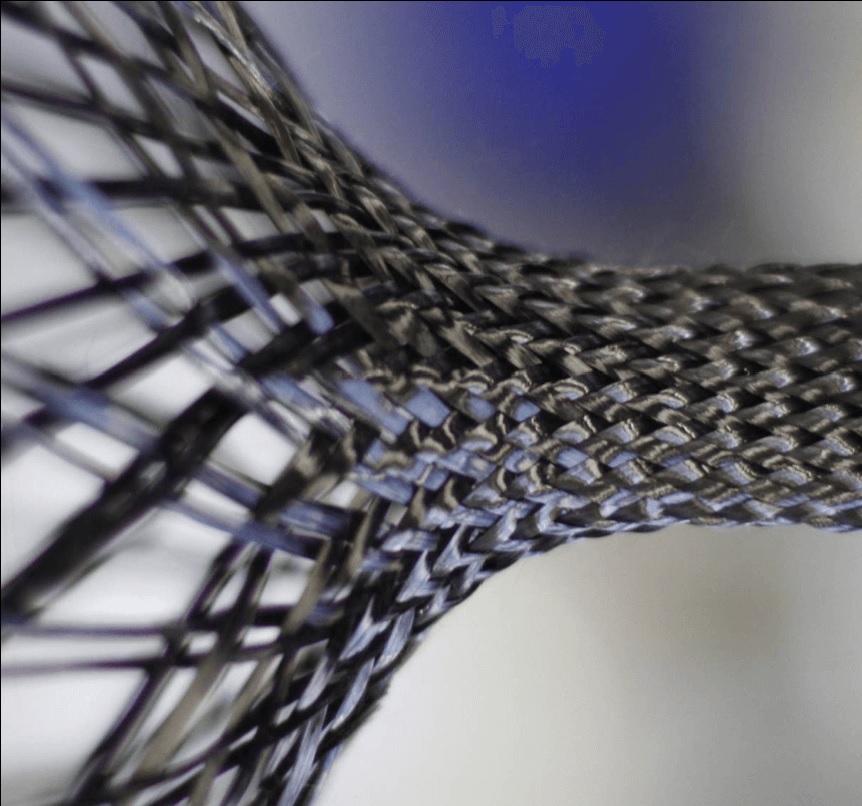

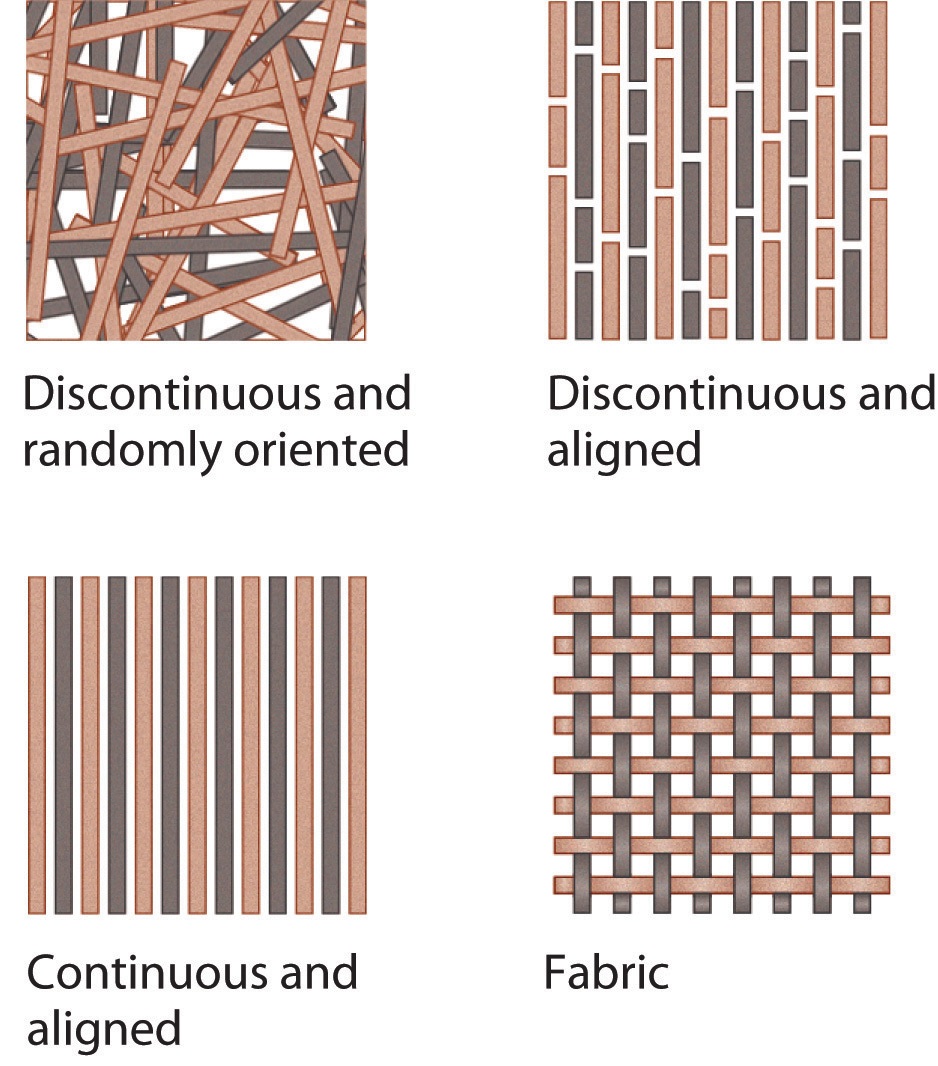

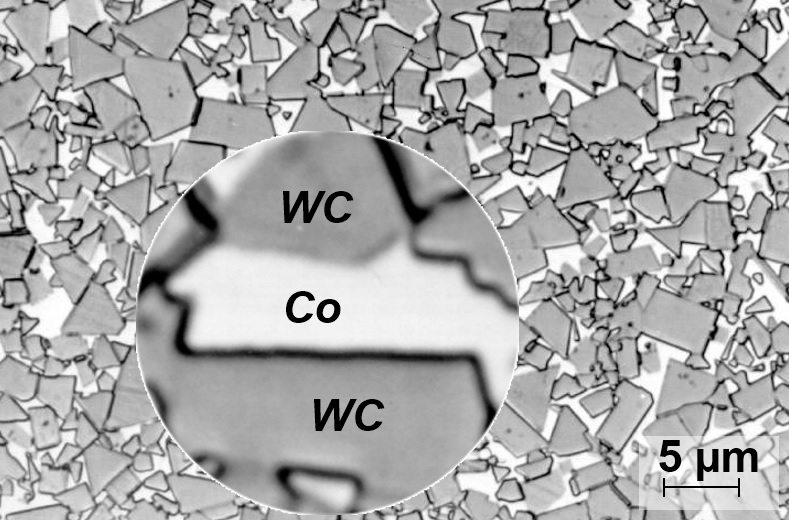

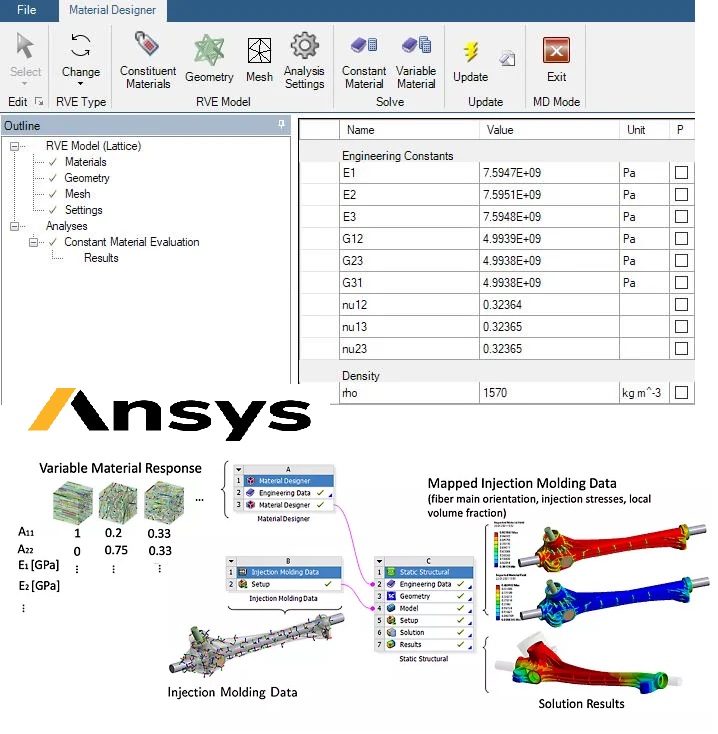

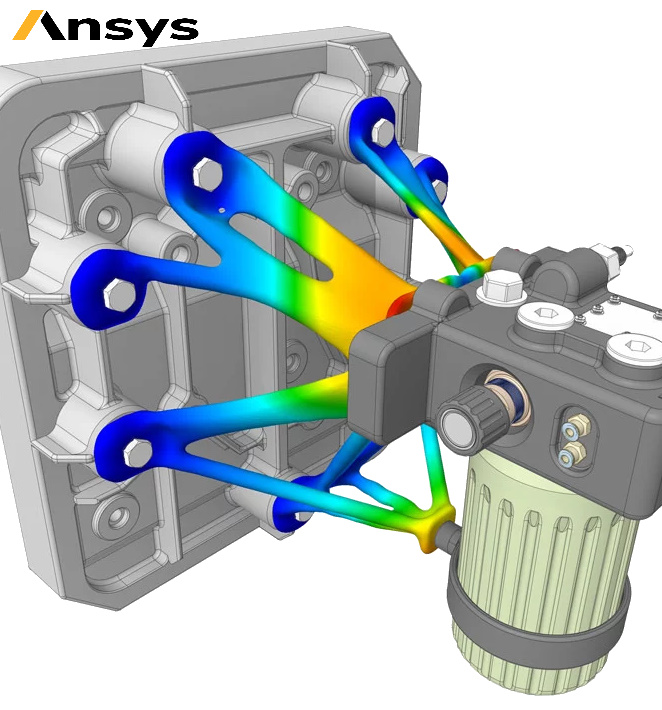

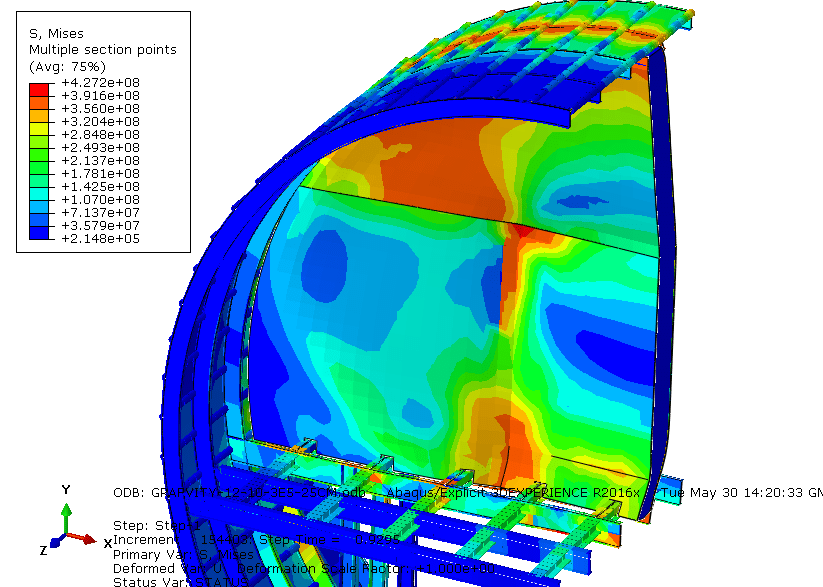

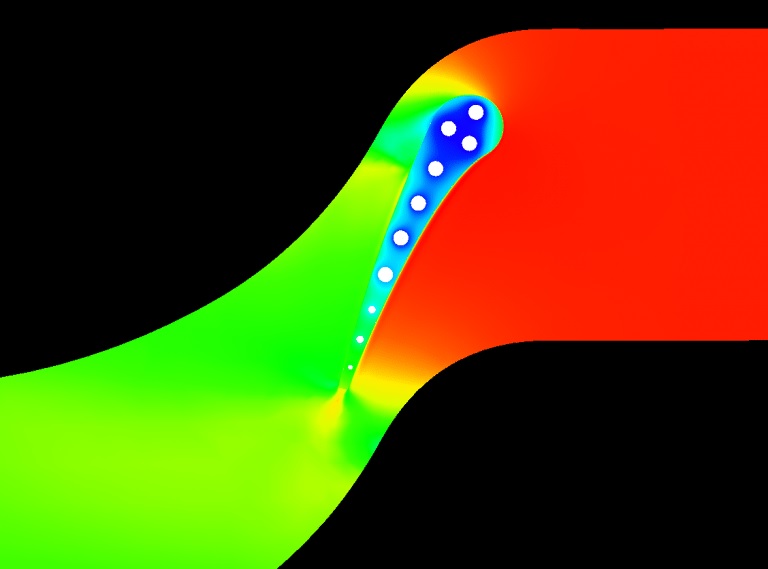

Advanced FEA tools are essential for material investigations and are used to simulate the behavior of materials under various loading conditions. An advanced woven model is a type of finite element model that is capable of accurately representing the underlying weave pattern and yarn structure of composite materials.

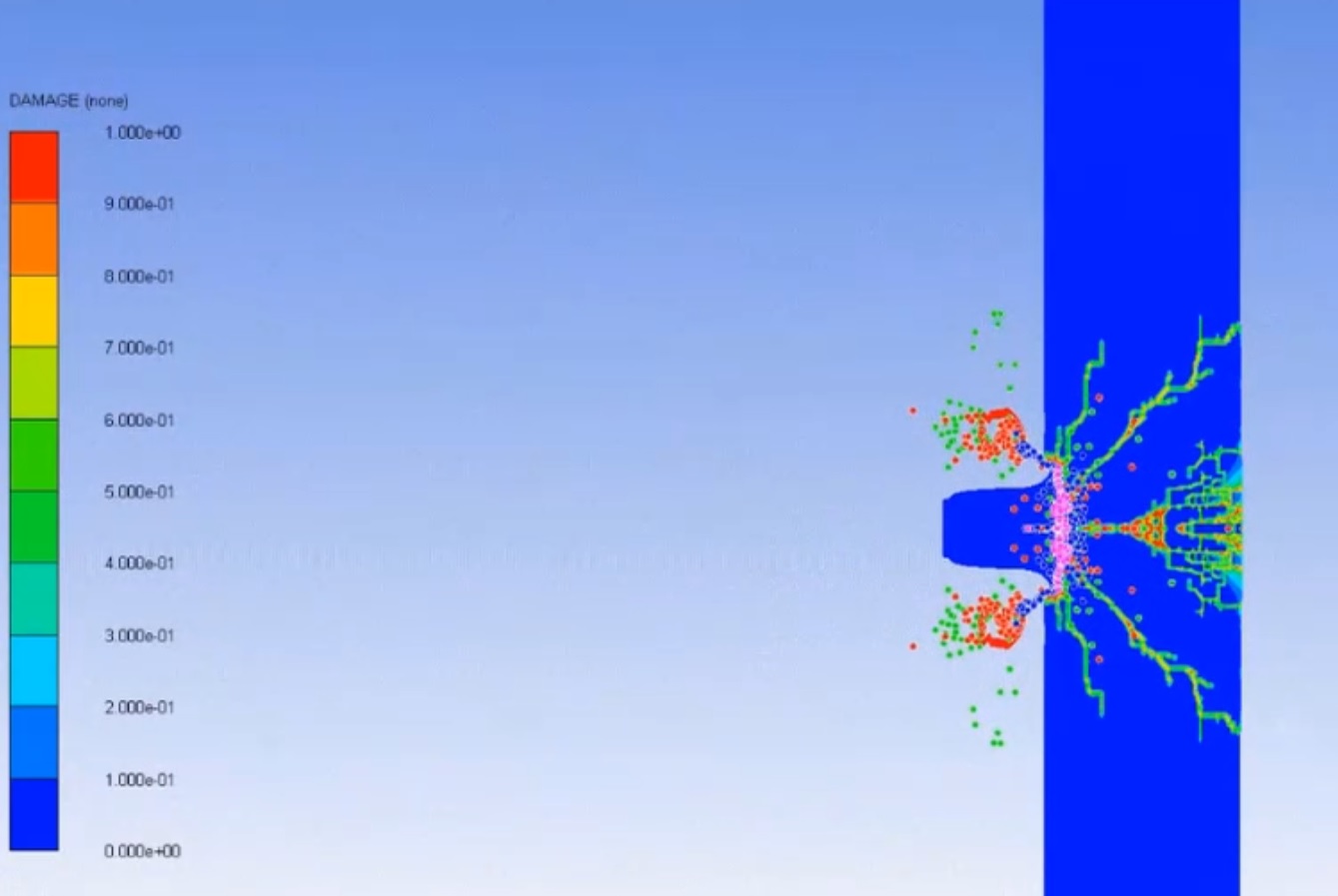

By taking into account the underlying weave pattern and yarn structure, advanced woven models can accurately simulate the mechanical behavior of composite materials under different loading conditions, including tension, compression, bending, and shear. This allows for the prediction of material properties such as stiffness, strength, and fracture toughness, which are critical for the design and optimization of composite components.

In addition, advanced woven models can also consider weave patterns in which the warp yarns go across multiple layers of weft yarns. These types of weave patterns improve the interlaminar toughness and impact resistance of the material, making it more resistant to damage and failure.

Structural analyses based on local warp/weft information from draping simulations can also be set up using advanced FEA tools. This allows for the accurate prediction of the mechanical behavior of composite materials during the manufacturing process, which is critical for ensuring the quality and performance of the final product.