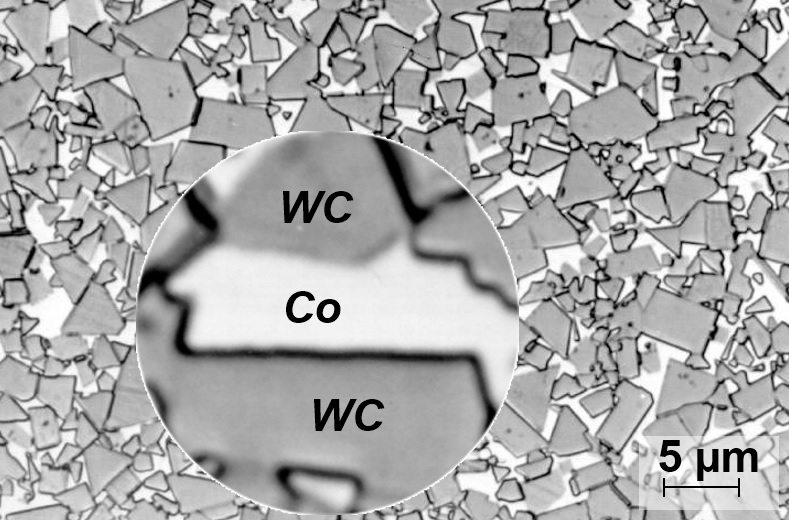

Hard metals, also known as cemented carbides, are composite materials that are made up of a metal matrix and a hard ceramic phase. The metal matrix typically consists of cobalt, nickel, or iron, while the hard ceramic phase is composed of tungsten carbide, titanium carbide, or tantalum carbide.

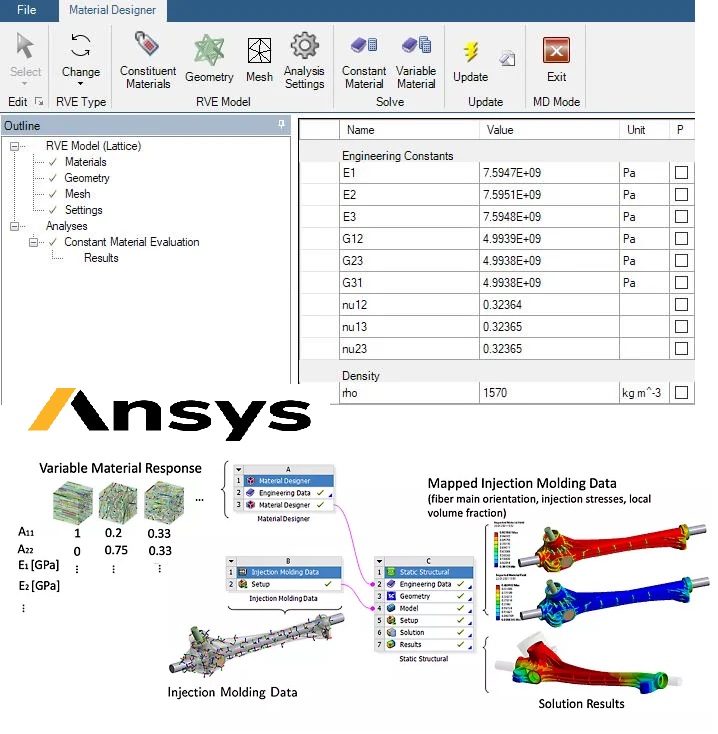

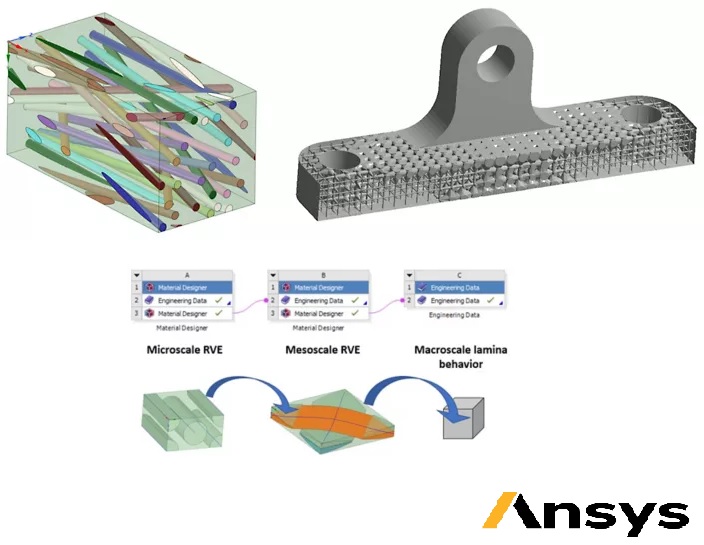

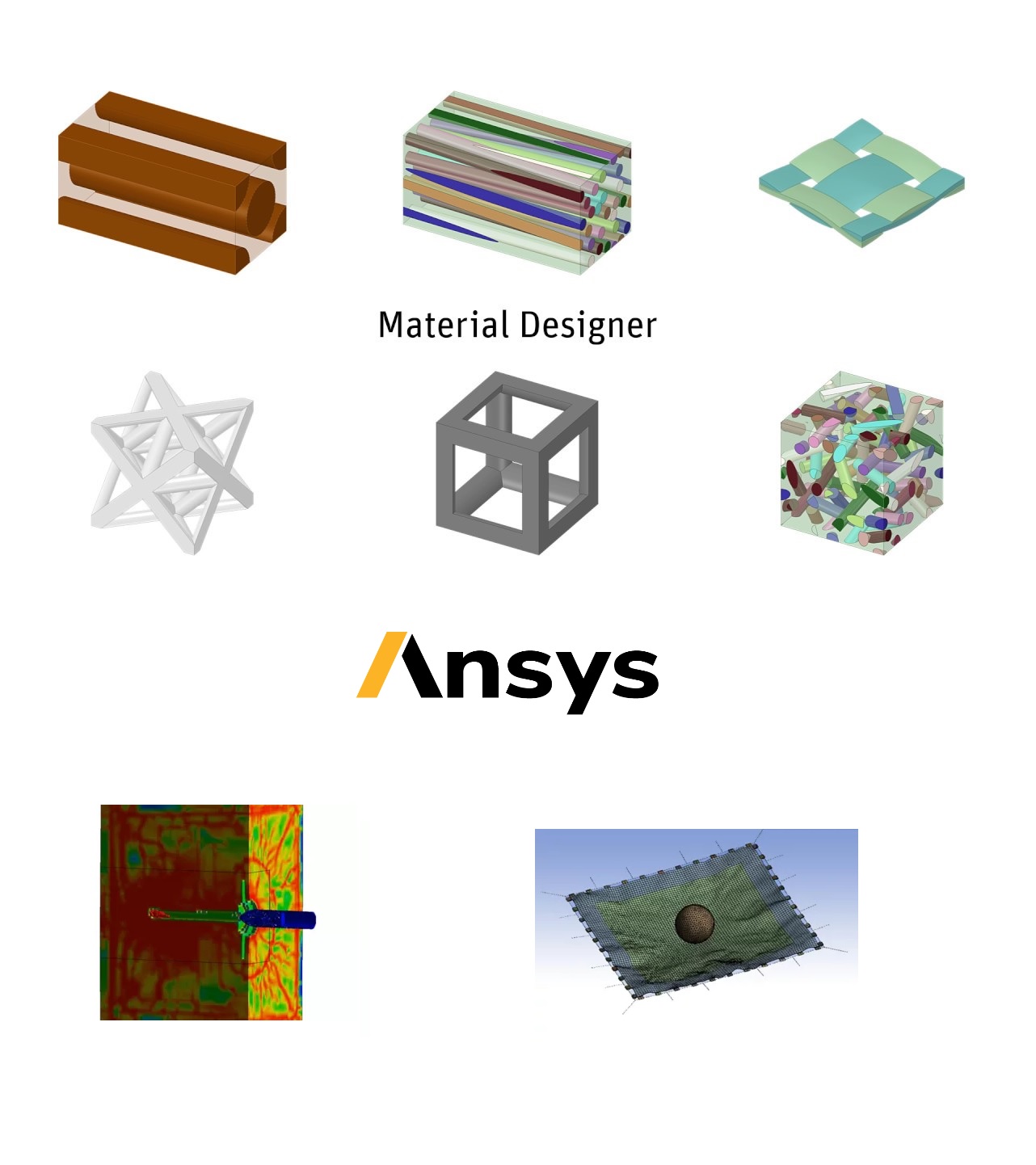

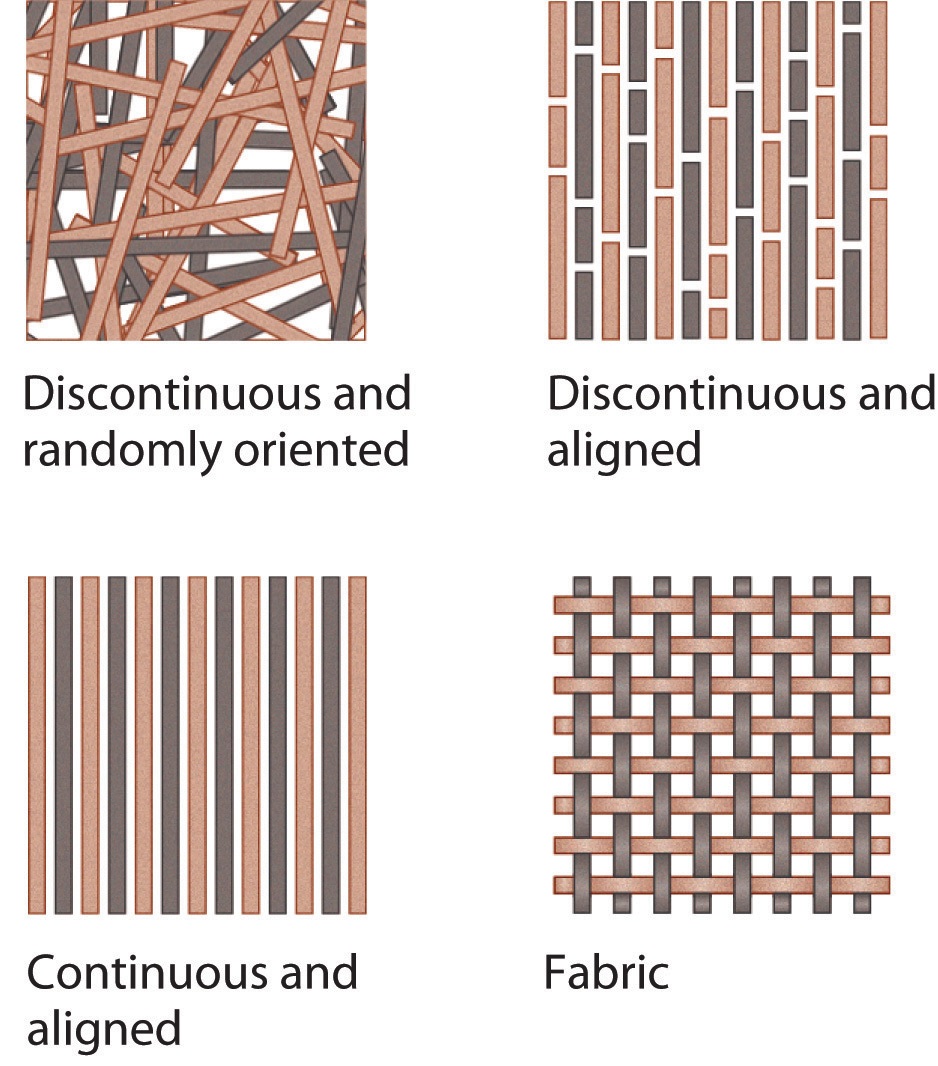

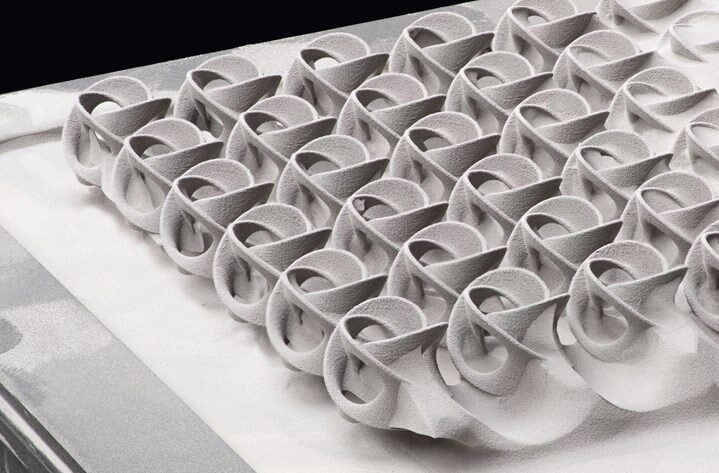

The microstructure of hard metals is critical to their mechanical properties, as it determines the distribution and size of the hard ceramic inclusions within the metal matrix. By varying the content and microstructure of the hard inclusion phase, it is possible to tune the material properties of the hard metal, including its hardness, strength, and wear resistance.

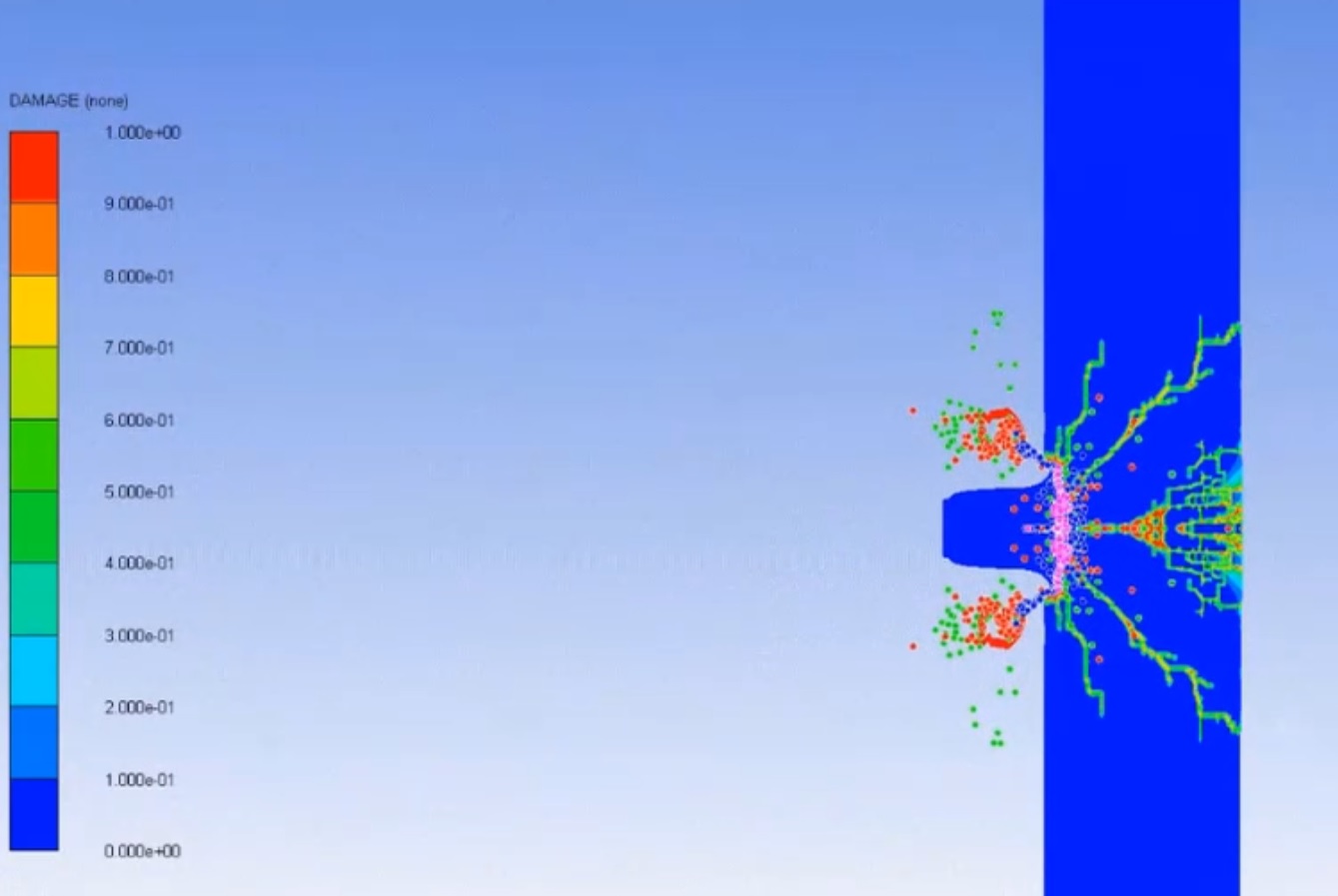

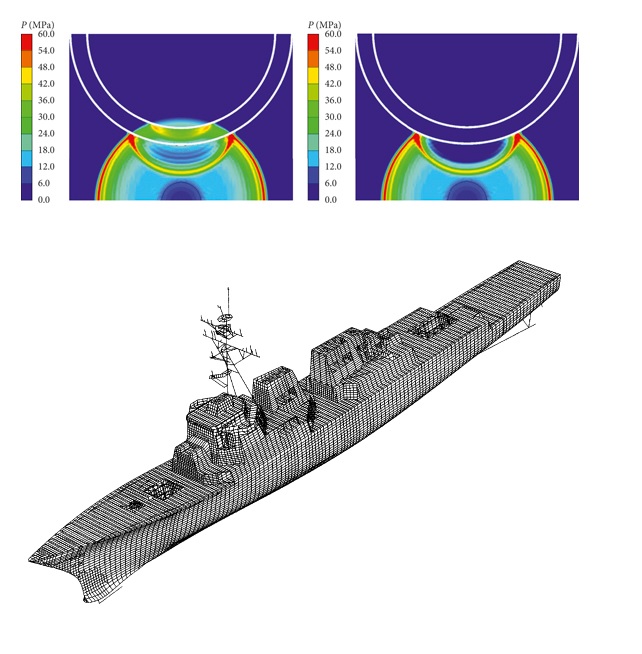

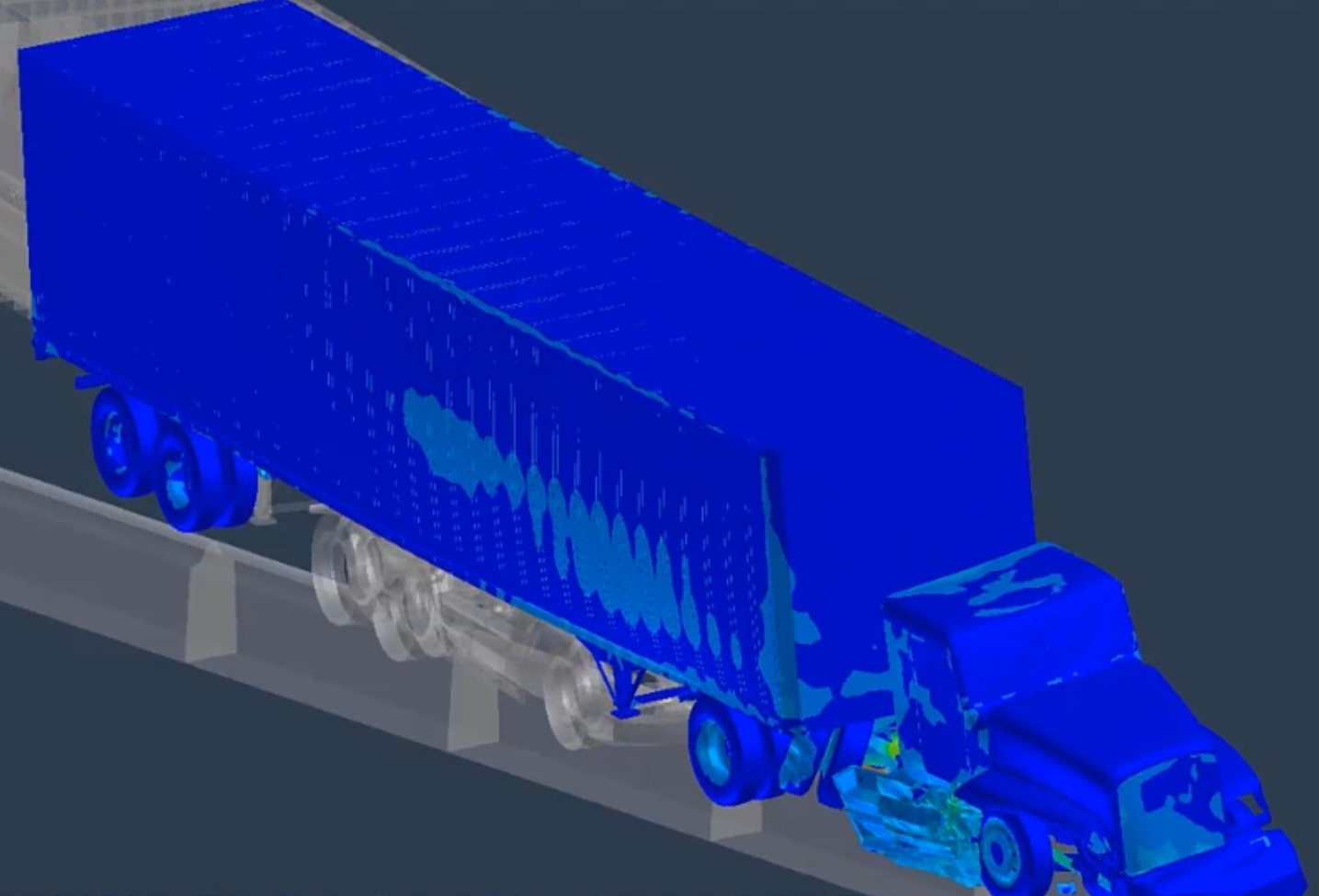

One key challenge in optimizing the microstructure of hard metals is managing the stresses that are generated during the manufacturing process. These stresses can lead to cracking or deformation of the material, which can affect its mechanical properties and overall performance. To mitigate these stresses, it is important to carefully control the manufacturing process, including the composition of the metal matrix and the processing conditions, such as temperature, pressure, and cooling rate.