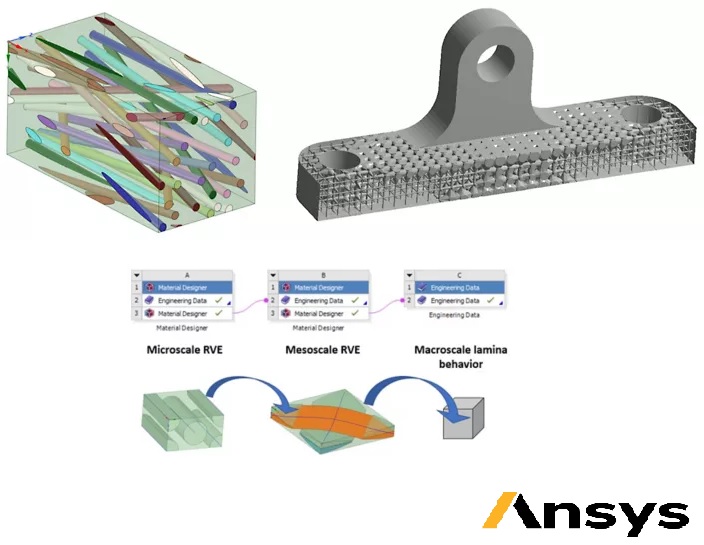

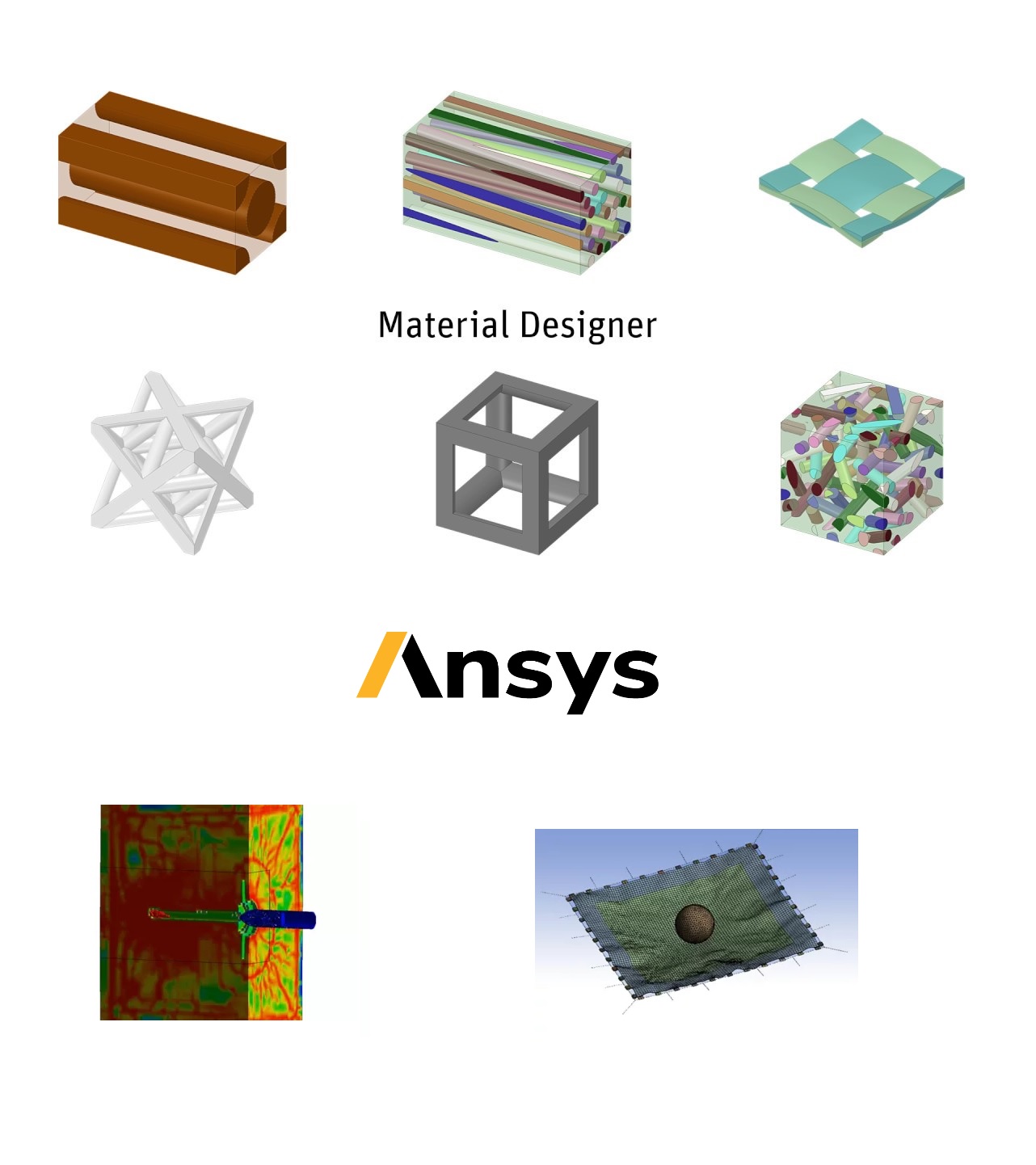

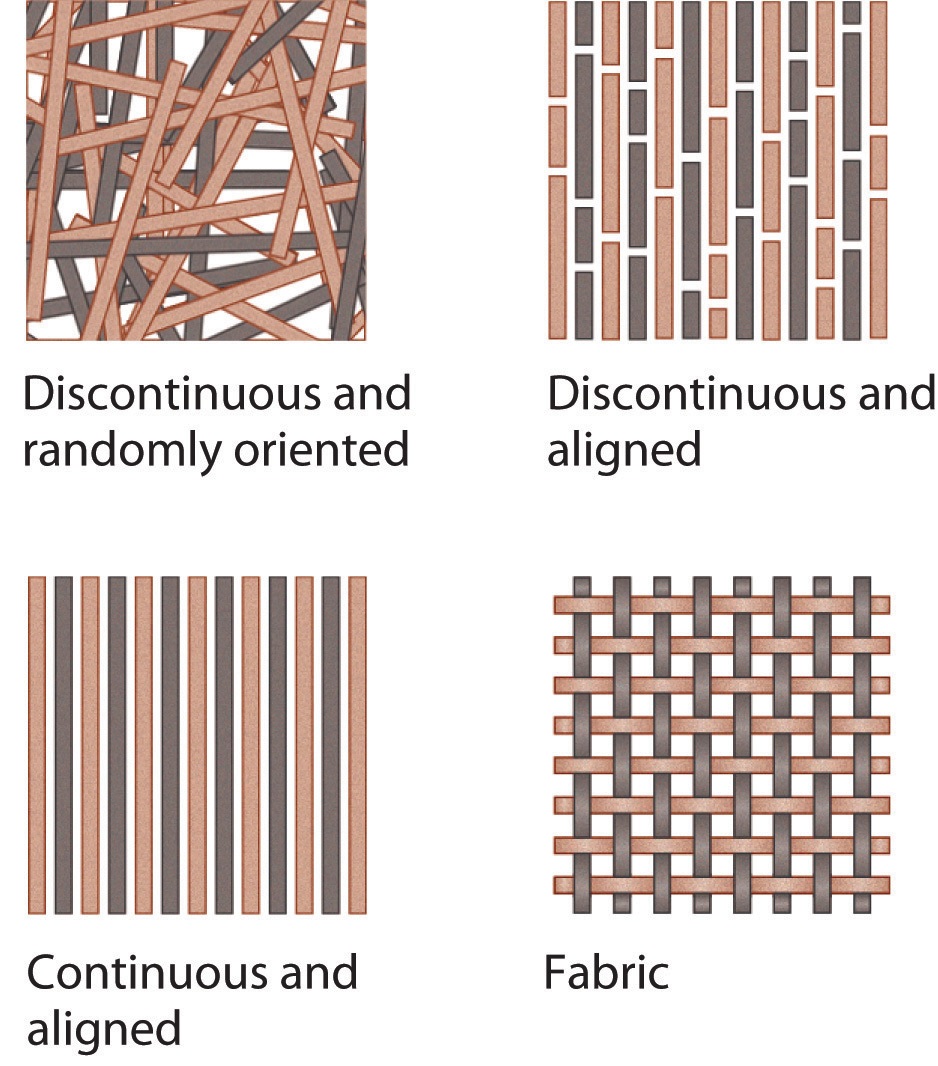

Discontinuous Fiber Composites

explore

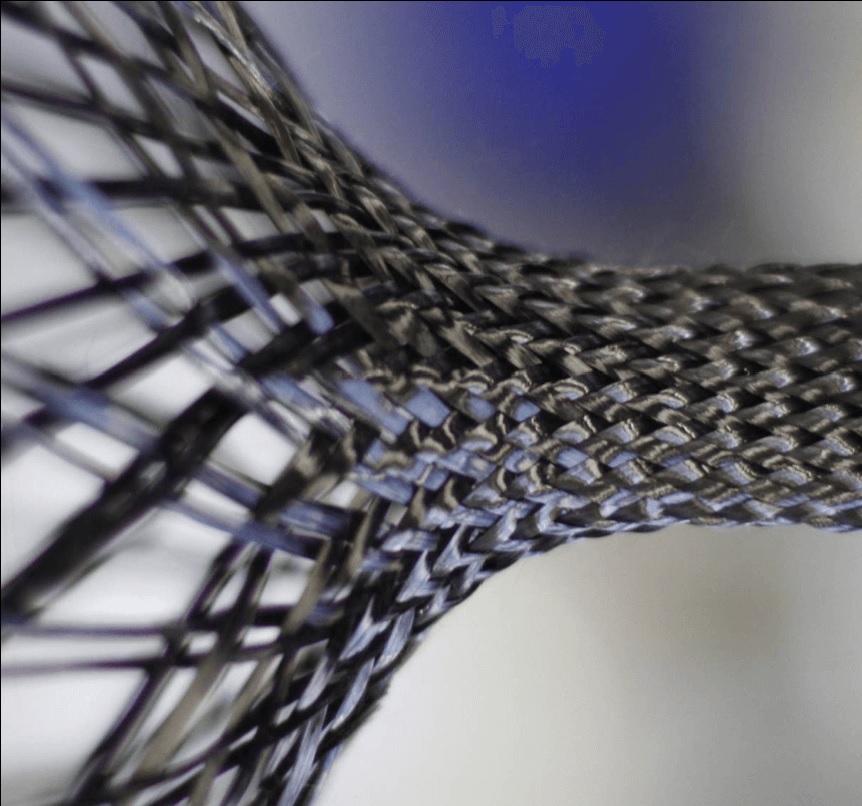

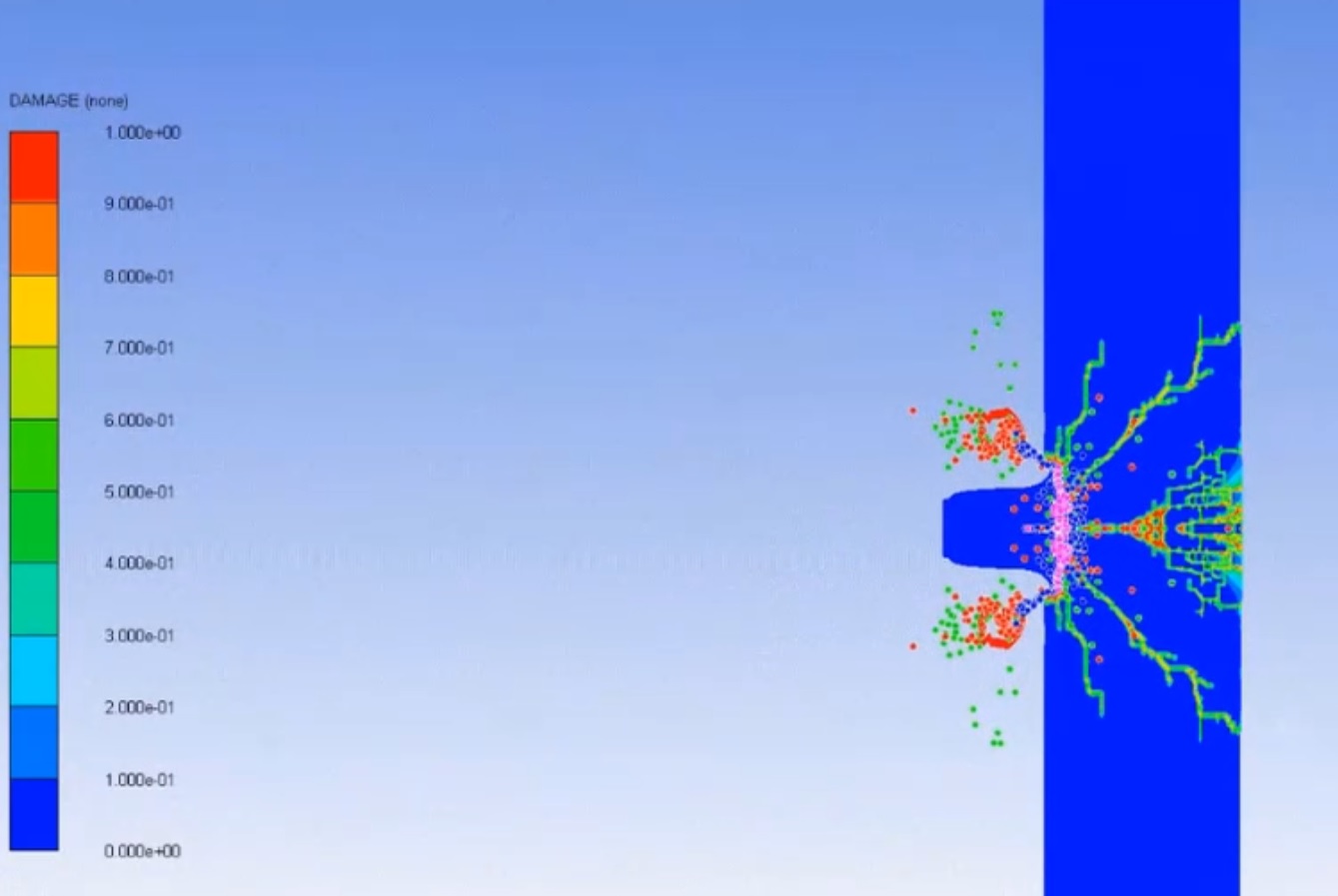

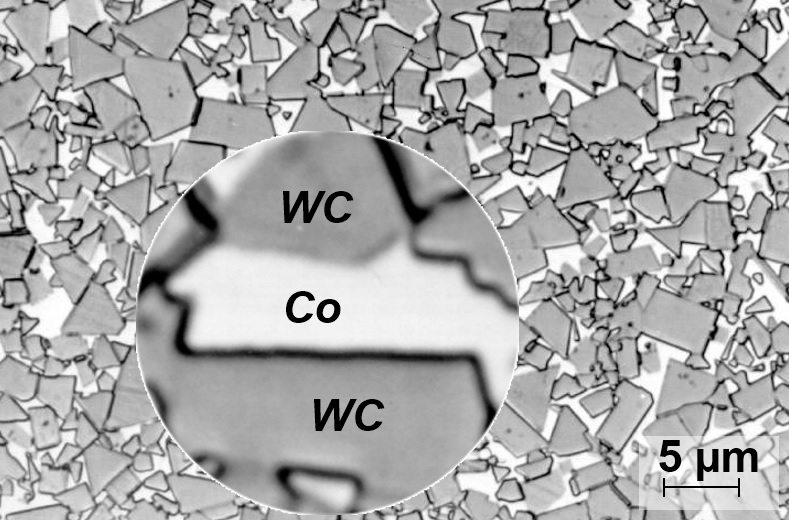

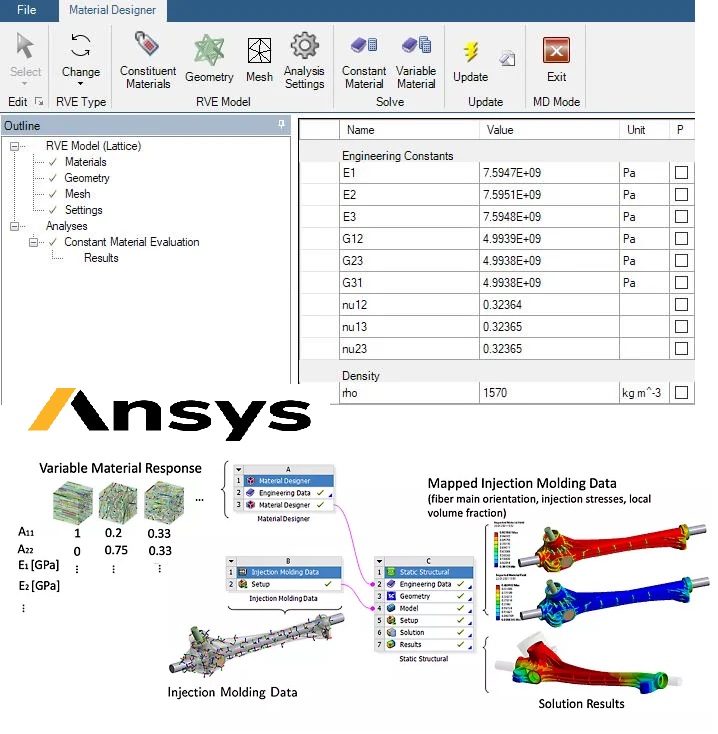

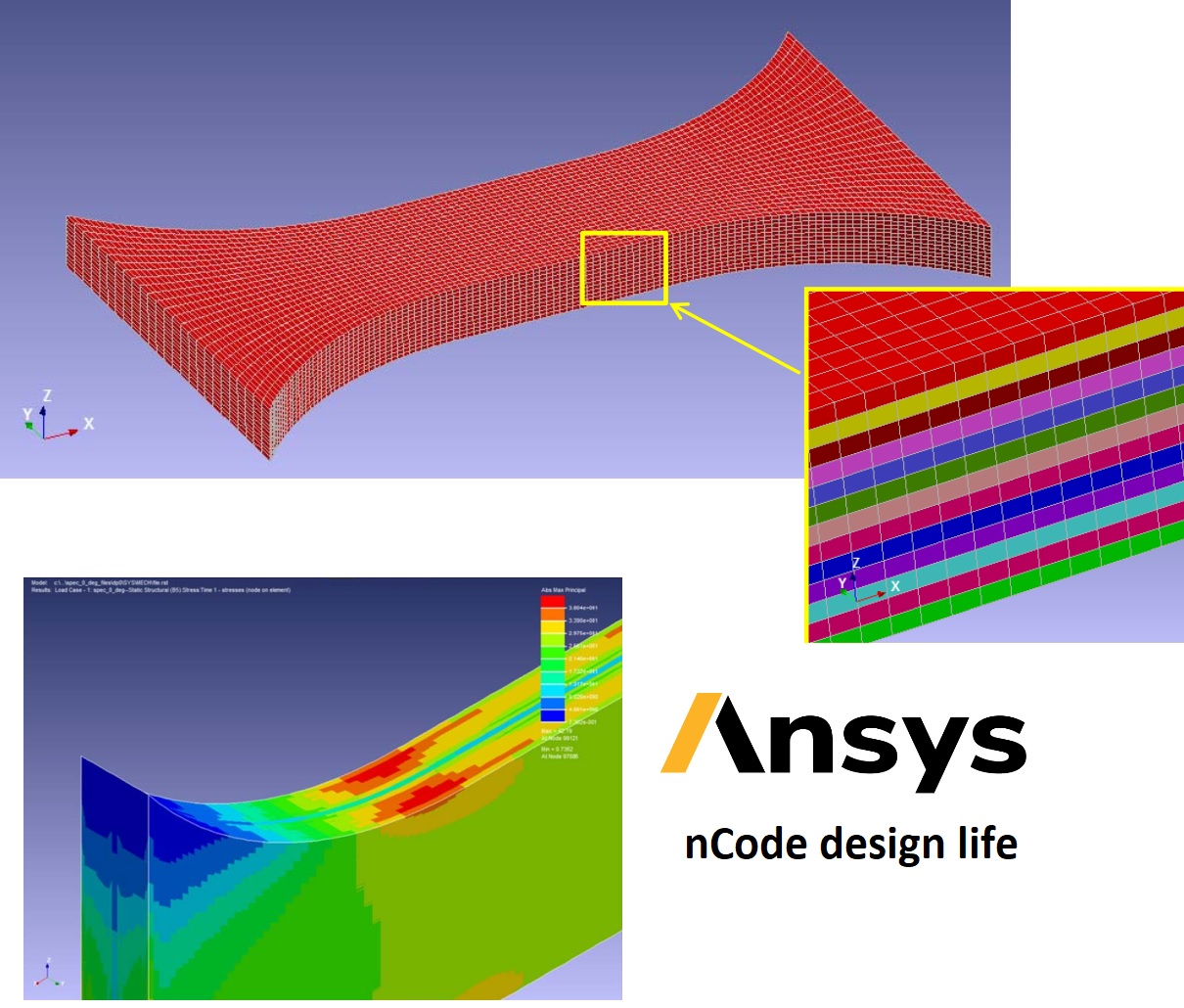

Discontinuous fiber composites (DFC) are a type of composite material that are made by compressing pre-impregnated fiber chips, or prepreg chips, which consist of unidirectional …

Discover More