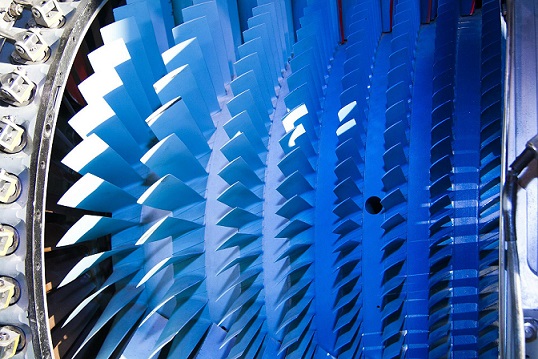

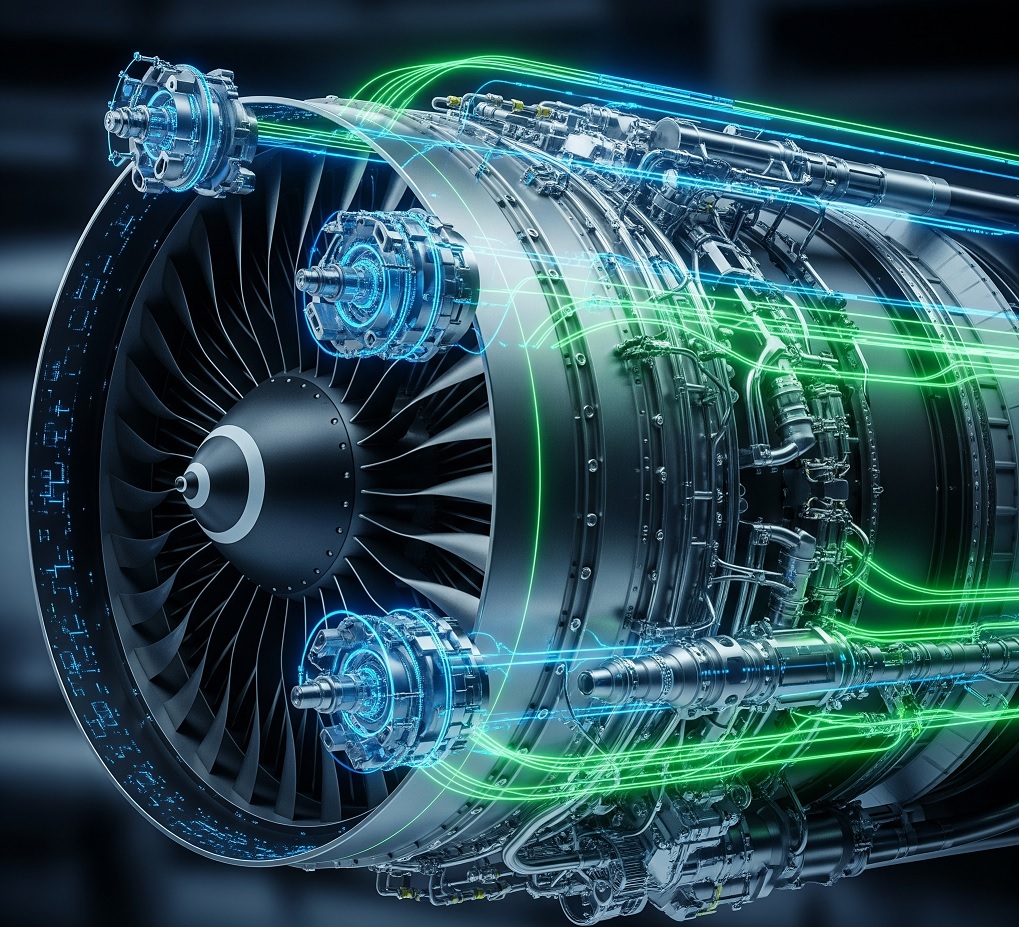

Gas turbine simulation is a process of modeling and analyzing the behavior of gas turbines under various operating conditions. It involves the use of CFD models and simulations to study the dynamics of gas turbine systems, including the spray, combustion, emissions, shaft and gear systems, and acoustic enclosures.

Key aspects of gas turbine simulation:

-

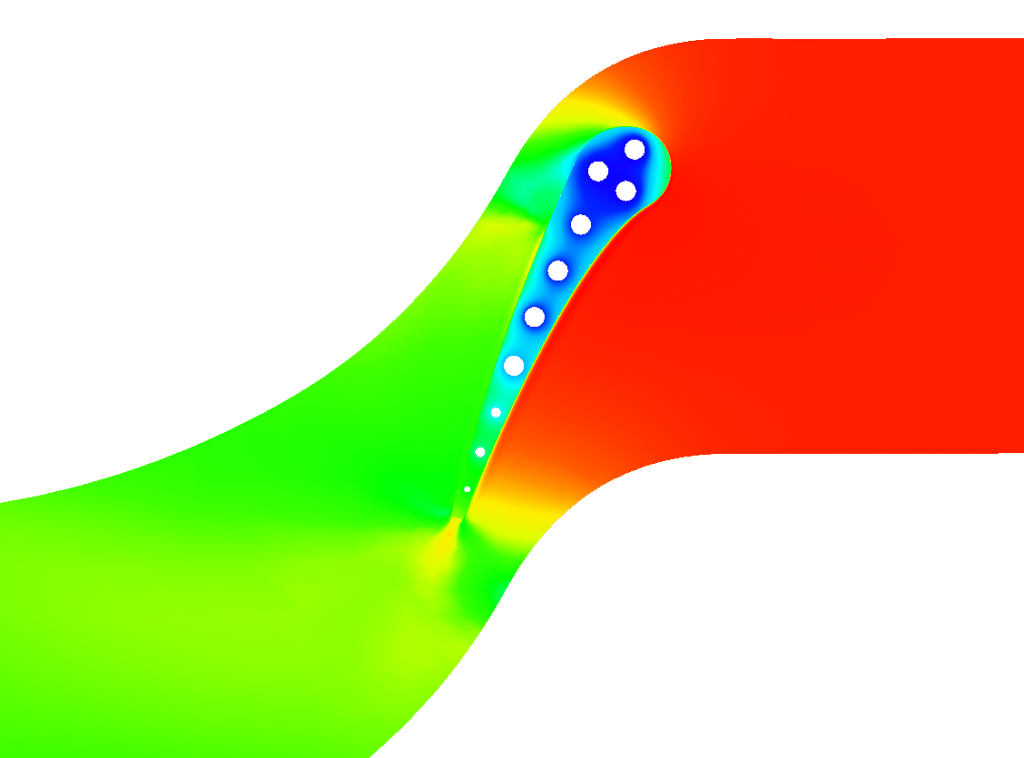

▶ Spray simulation: Gas turbine engines use fuel injection systems to spray fuel into the combustion chamber. Spray simulation involves modeling the behavior of the fuel spray, including the droplet size, velocity, and trajectory. This helps in optimizing the fuel injection system for maximum efficiency and minimizing emissions.

-

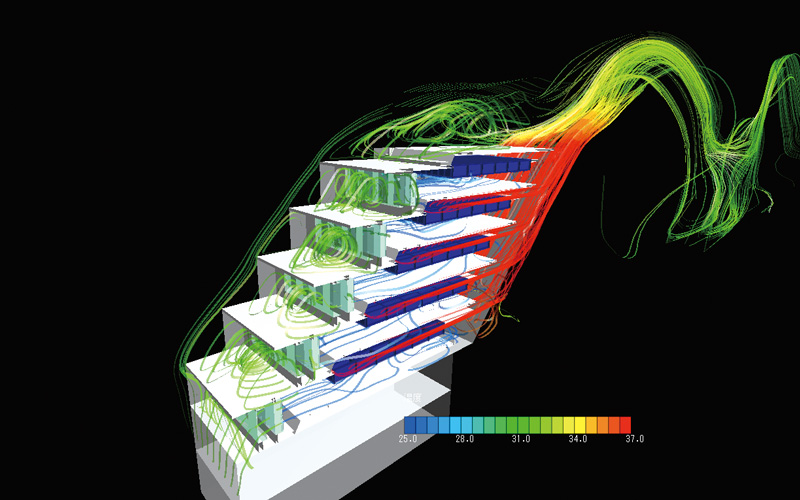

▶ Combustion simulation: Combustion simulation involves modeling the chemical reactions that occur inside the combustion chamber of the gas turbine engine. This helps in predicting the performance of the combustion process, including the temperature and pressure profiles, flame stability, and emissions.

-

▶ Emissions simulation: Emissions simulation involves modeling the emissions produced by the gas turbine engine, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). This helps in optimizing the combustion process to minimize emissions and meet regulatory requirements.

-

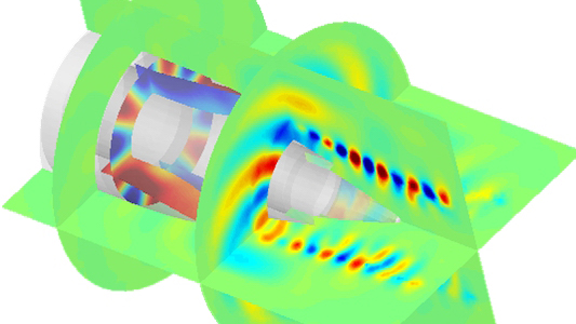

▶ Shaft and gear system simulation: Gas turbine engines use shafts and gears to transmit power from the turbine to the compressor and other components. Shaft and gear system simulation involves modeling the dynamics of these systems to optimize their performance, reduce vibration and noise, and improve reliability.

-

▶ Acoustic enclosure simulation: Gas turbine engines are often enclosed in acoustic enclosures to reduce noise pollution. Acoustic enclosure simulation involves modeling the acoustics of the enclosure to optimize its design for maximum noise reduction.