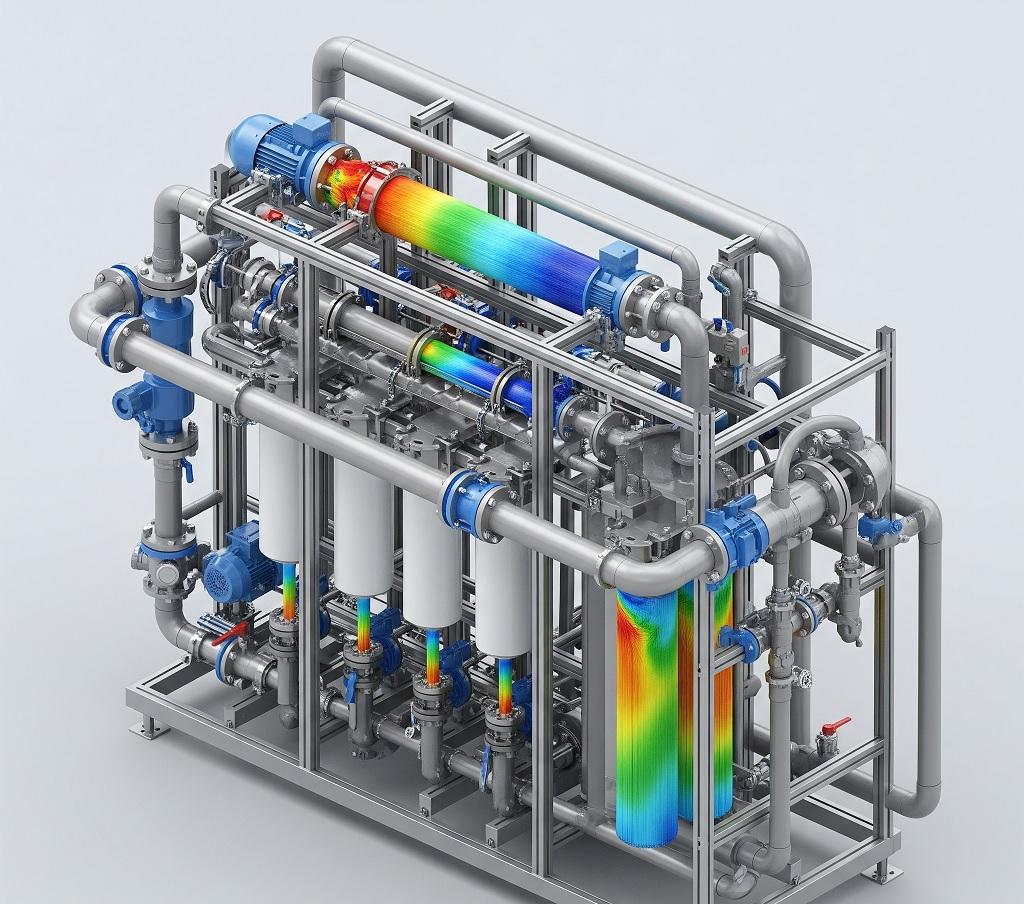

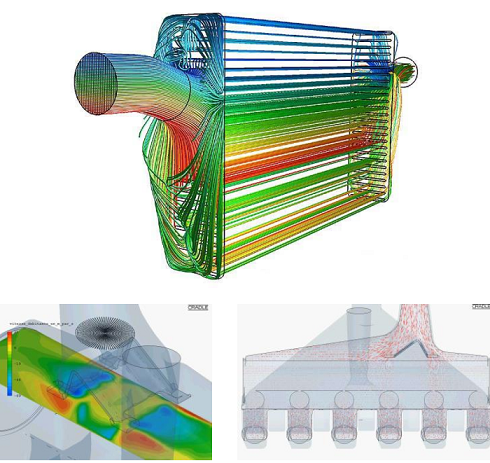

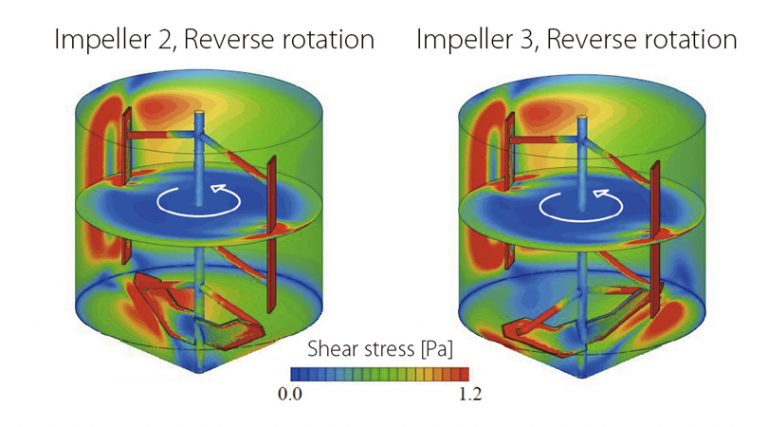

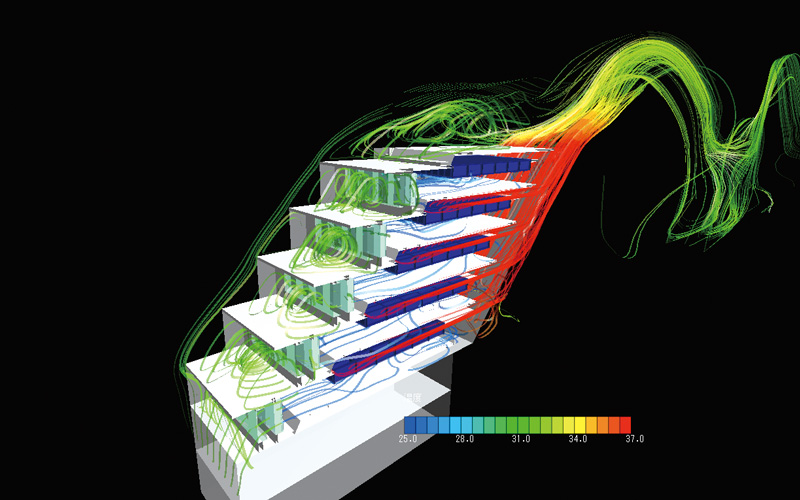

CFD simulation with detailed chemistry involves the use of reaction kinetics and thermodynamic data to model the chemical reactions occurring inside the reactor. The simulation can be used to model various types of reactors, including batch, semi-batch, and continuous flow reactors. The simulation takes into account the reaction mechanism, reaction rate, and heat transfer during the reaction to provide a comprehensive analysis of the reactor performance.

CFD simulation also allows engineers to optimize the design of the reactor by evaluating the impact of different operating conditions on the reaction efficiency and product quality. For example, CFD simulation can be used to determine the optimal reactor temperature, pressure, and flow rates for maximum product yield and quality.

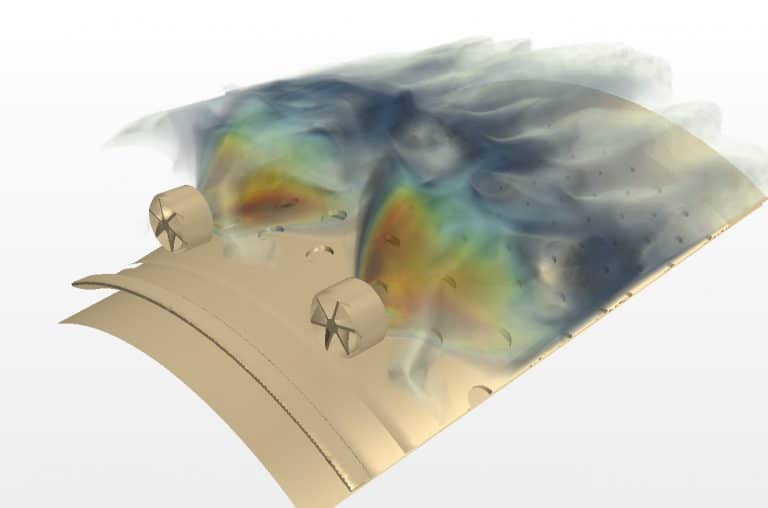

In addition to reactor design, CFD simulation is also used in combustion processes for chemical processing. Combustion involves the reaction of fuel with oxygen to produce heat and products, such as carbon dioxide and water. CFD simulation can be used to model the combustion process, including the flow of fuel and air, combustion chemistry, and heat transfer. This simulation allows engineers to optimize the combustion process for maximum efficiency and minimum emissions.