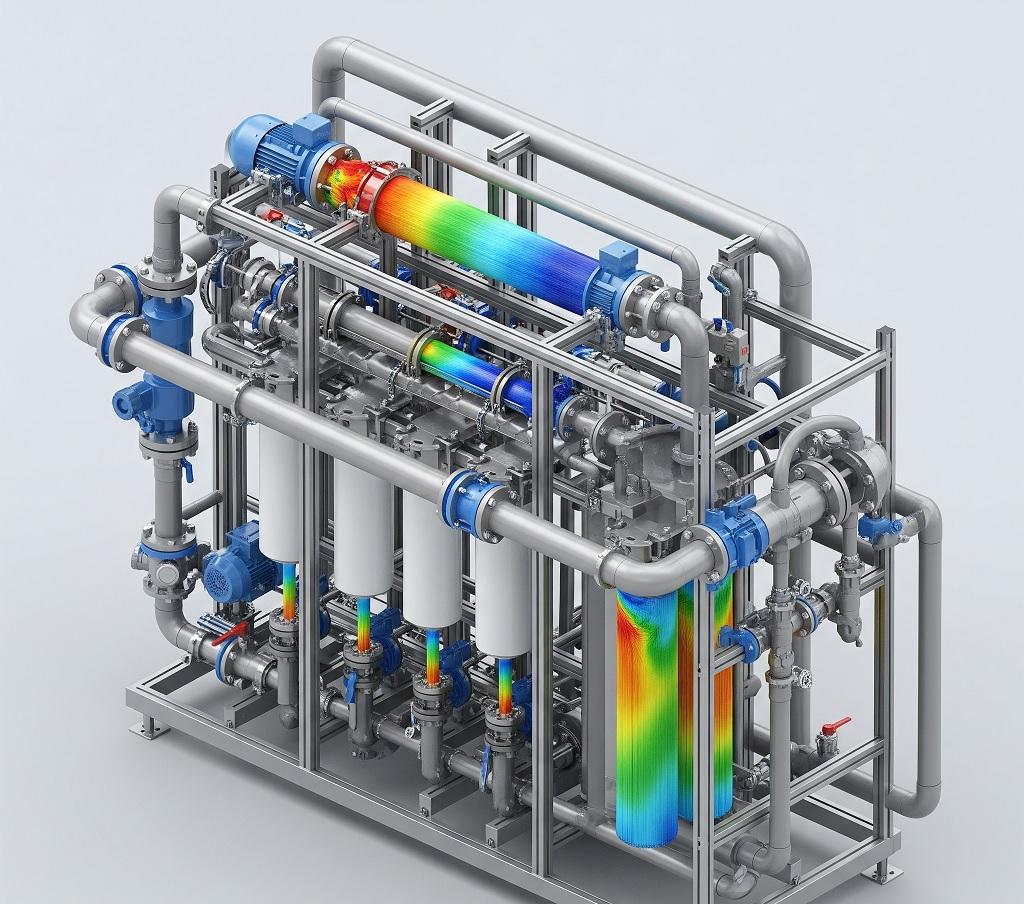

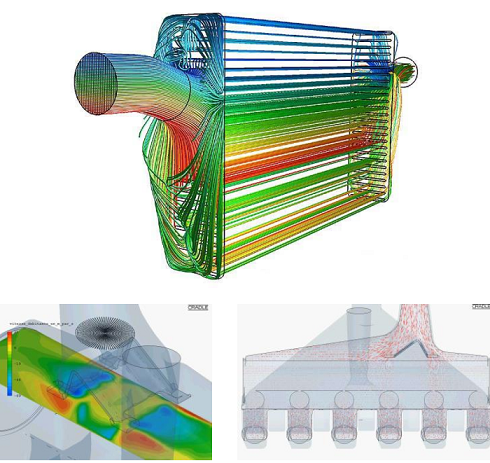

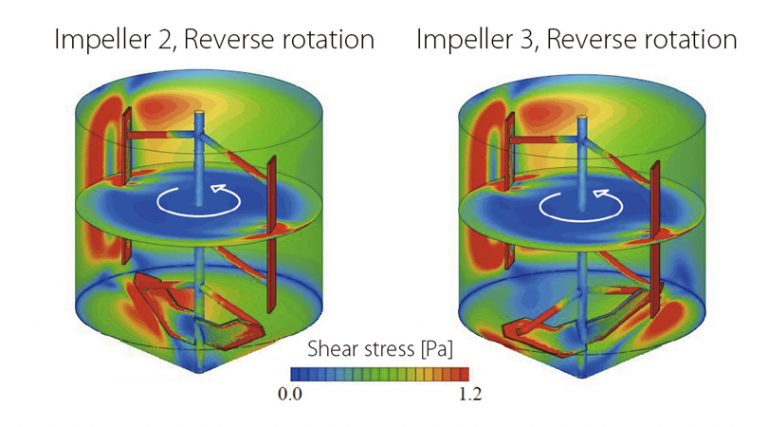

One common application of multiphase simulation in chemical processing is in the design and optimization of mixing and separation processes. These processes involve the interaction of multiple phases, such as gases, liquids, and solids, and are critical to the production of many chemical products. Multiphase simulation allows engineers to optimize mixing and separation processes by predicting the behavior of the different phases under various operating conditions, such as flow rates and temperatures.

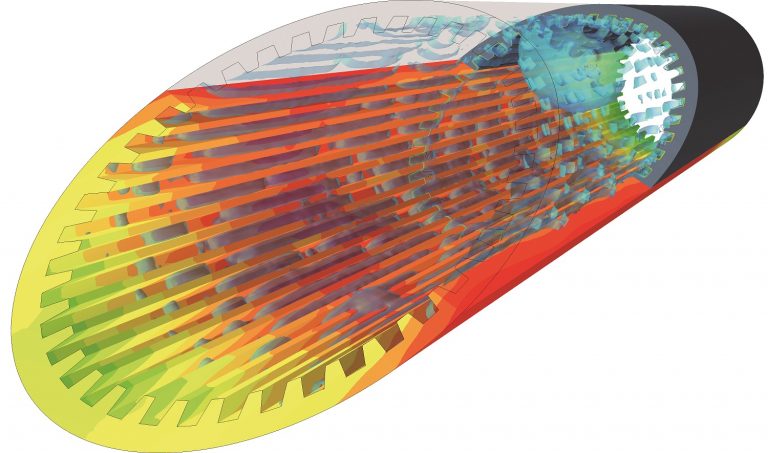

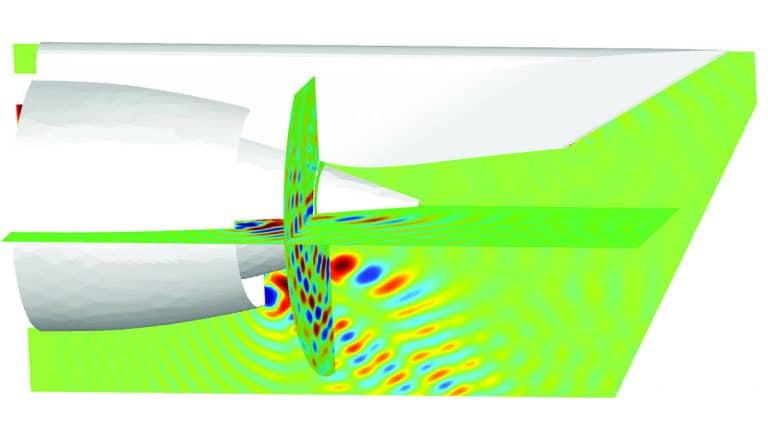

Another application is the design and optimization of reactors. Reactors are used in many chemical processes to convert raw materials into desired products. Multiphase simulation allows engineers to optimize reactor design by predicting the behavior of the different phases, such as gas-liquid or liquid-solid, and optimizing the reactor geometry and operating conditions for maximum efficiency and product yield.

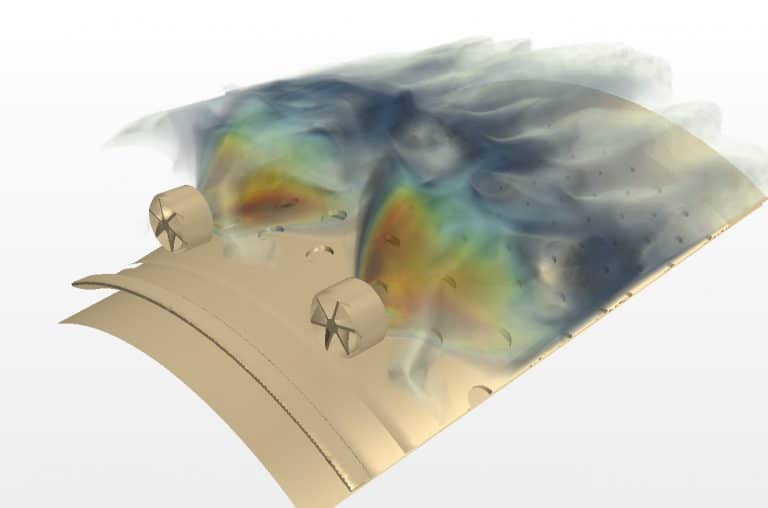

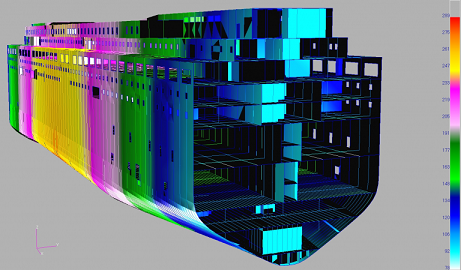

In addition, multiphase simulation is also used in the design and optimization of fluidized bed reactors, which are commonly used in the production of petrochemicals and in the refining of petroleum products. Fluidized bed reactors involve the movement of solid particles in a fluidized bed, and multiphase simulation allows engineers to optimize reactor design by predicting the behavior of the solid particles and their interaction with the fluid phase.