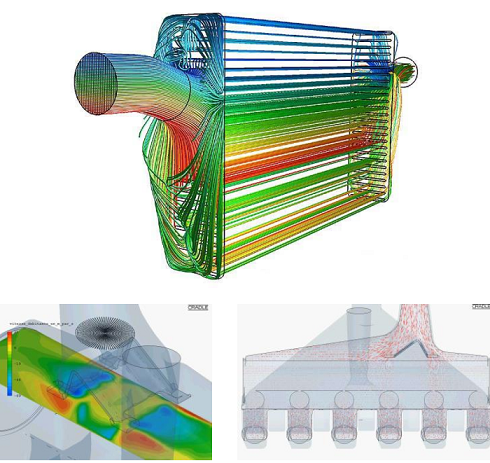

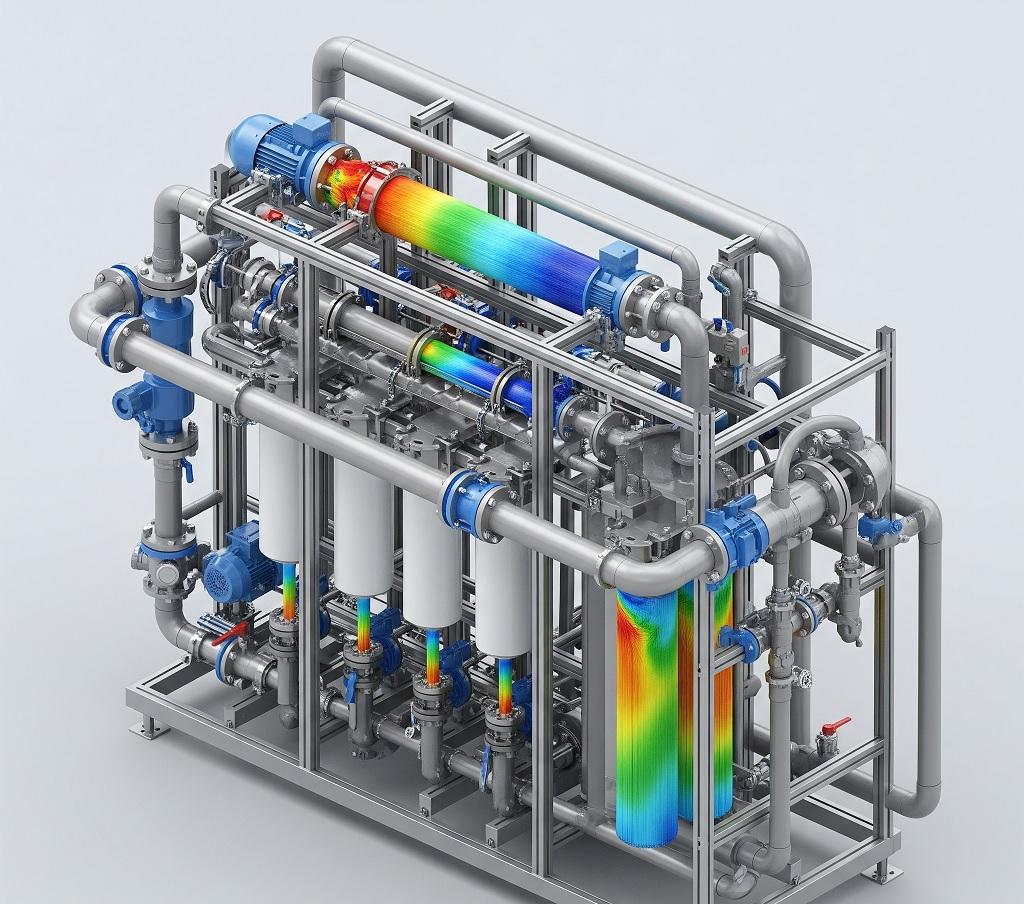

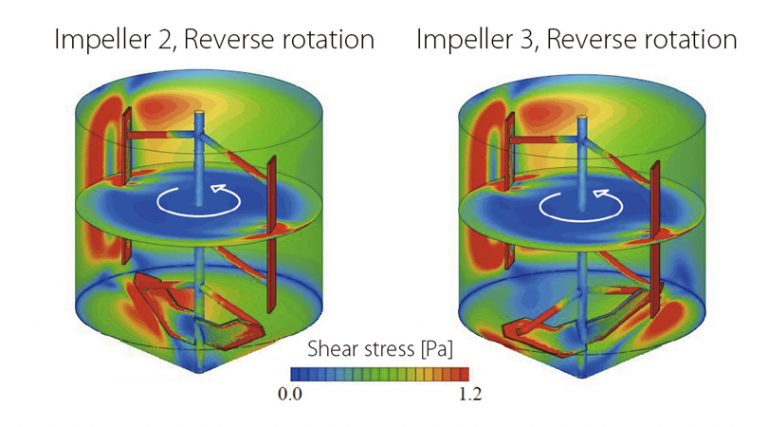

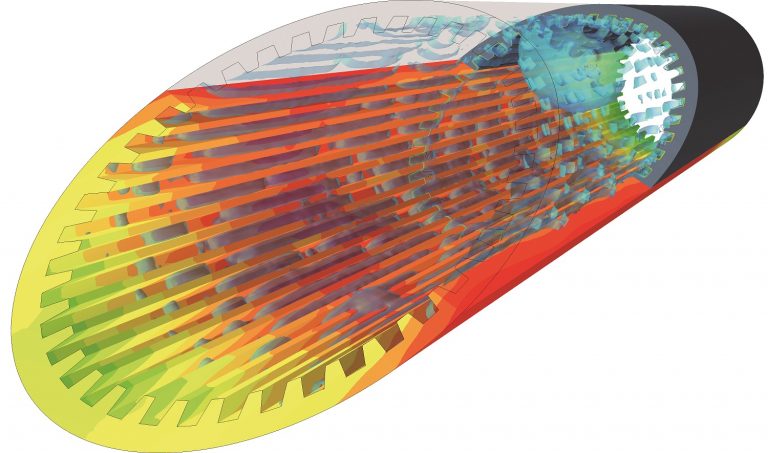

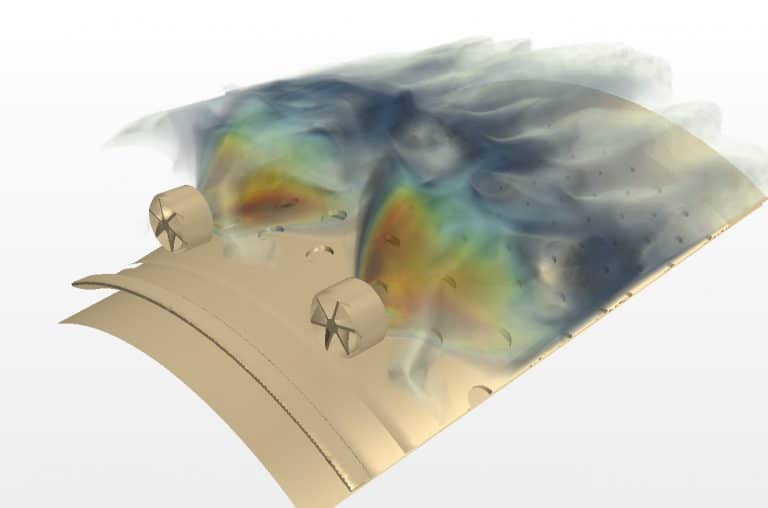

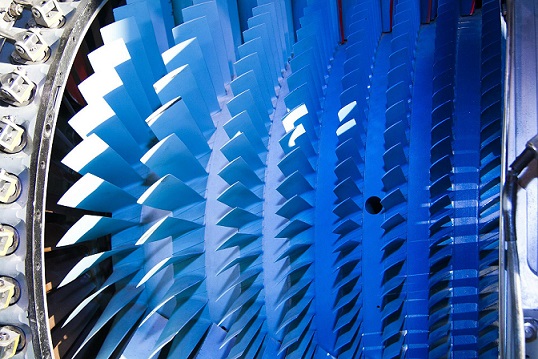

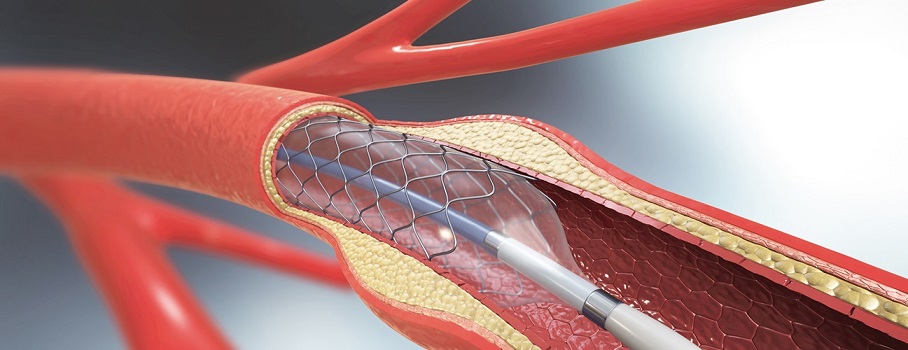

Designing effective filtration systems is critical in many industries, including chemical processing, food and beverage, pharmaceuticals, and water treatment. CFD simulations can be used to model the transport of solid particles in these systems, helping to understand and reduce erosion in solid separation and extraction devices.

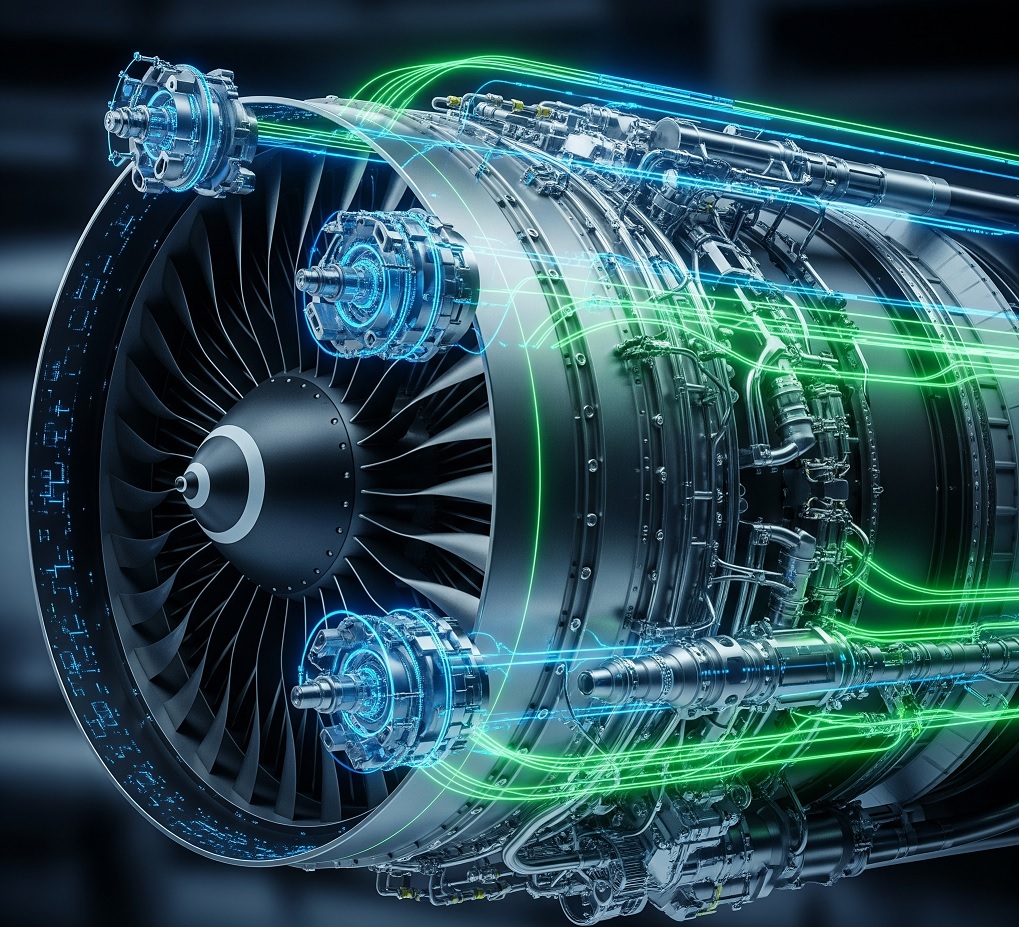

FEA and CFD simulations can be used to optimize filtration systems by studying filter media, particle deposition and caking, pressure drop, throughput, and back flushing. By simulating these phenomena, it is possible to identify areas of inefficiency and suggest design improvements to optimize the filtration process.

In-depth studies of filter media can help to determine the optimal material and pore size distribution for a given application. Particle deposition and caking simulations can identify areas of high particle accumulation, which can lead to reduced throughput and increased pressure drop. By optimizing these factors, it is possible to improve the overall performance of the filtration system.

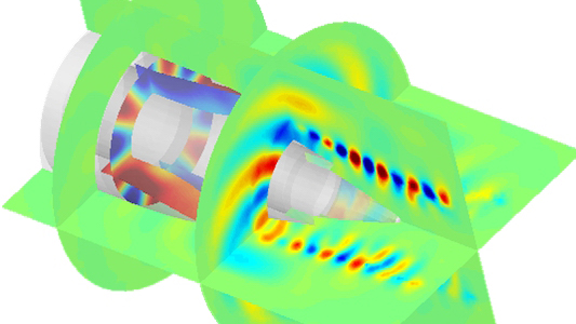

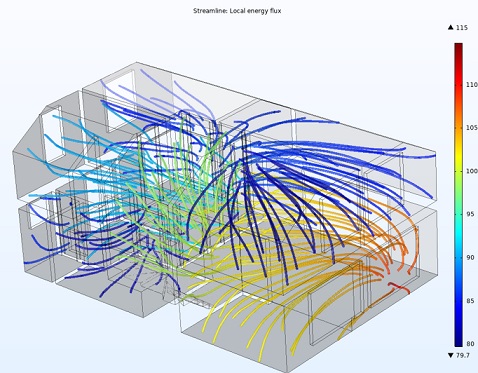

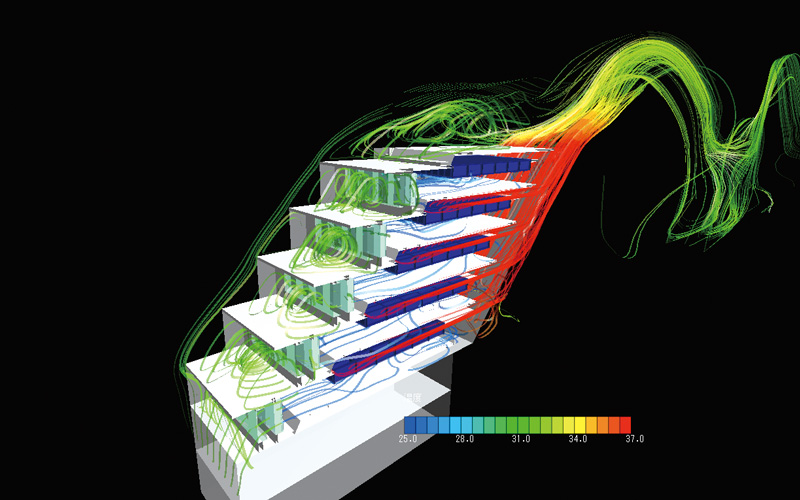

Pressure drop simulations can help to identify areas of high resistance in the filtration system, which can lead to decreased throughput and increased energy consumption. Throughput simulations can help to optimize the flow rate through the filtration system, ensuring that it operates at maximum efficiency.

Back flushing simulations can be used to optimize the cleaning process of the filtration system, ensuring that it is as efficient as possible. By simulating these processes, it is possible to minimize the amount of energy and resources required for cleaning, further improving the overall efficiency of the filtration system.