MultiObjective Design of Turbomachinery

Coupled CFD & FEA for Turbomachinery Aerodynamics, Hydrodynamics and Hydraulics, Thermodynamics, Acoustics and Vibration, Fatigue

MultiObjective Design of Turbomachinery

Artificial Intelligence Analysis

FEA|CFD & AI Integration

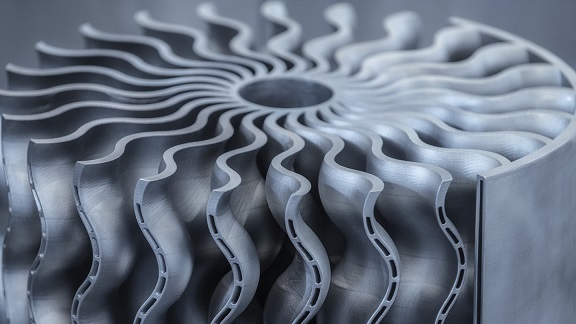

Optimizing the simulation driven design of turbomachinery such as compressors, turbines, pumps, blowers, turbochargers, turbopumps, centrifugal compressors, radial turbines, hydraulic turbines, low speed to transonic fans and torque converters offers enormous potential. Simulation Dynamics engineering team performs all stages of design and optimization of turbomachinery at the 1D, 2D and 3D levels including 3D blade design, FEA and CFD analysis.

Contact US and Discover Solutions