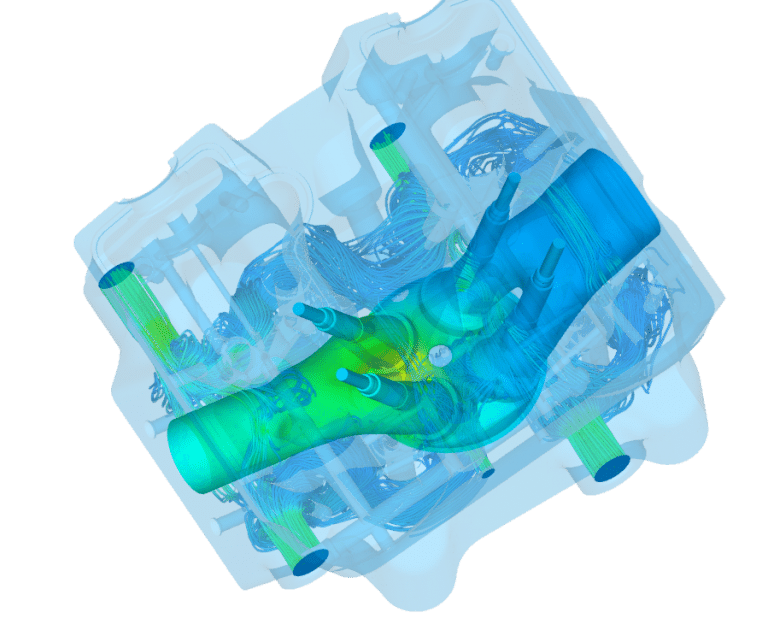

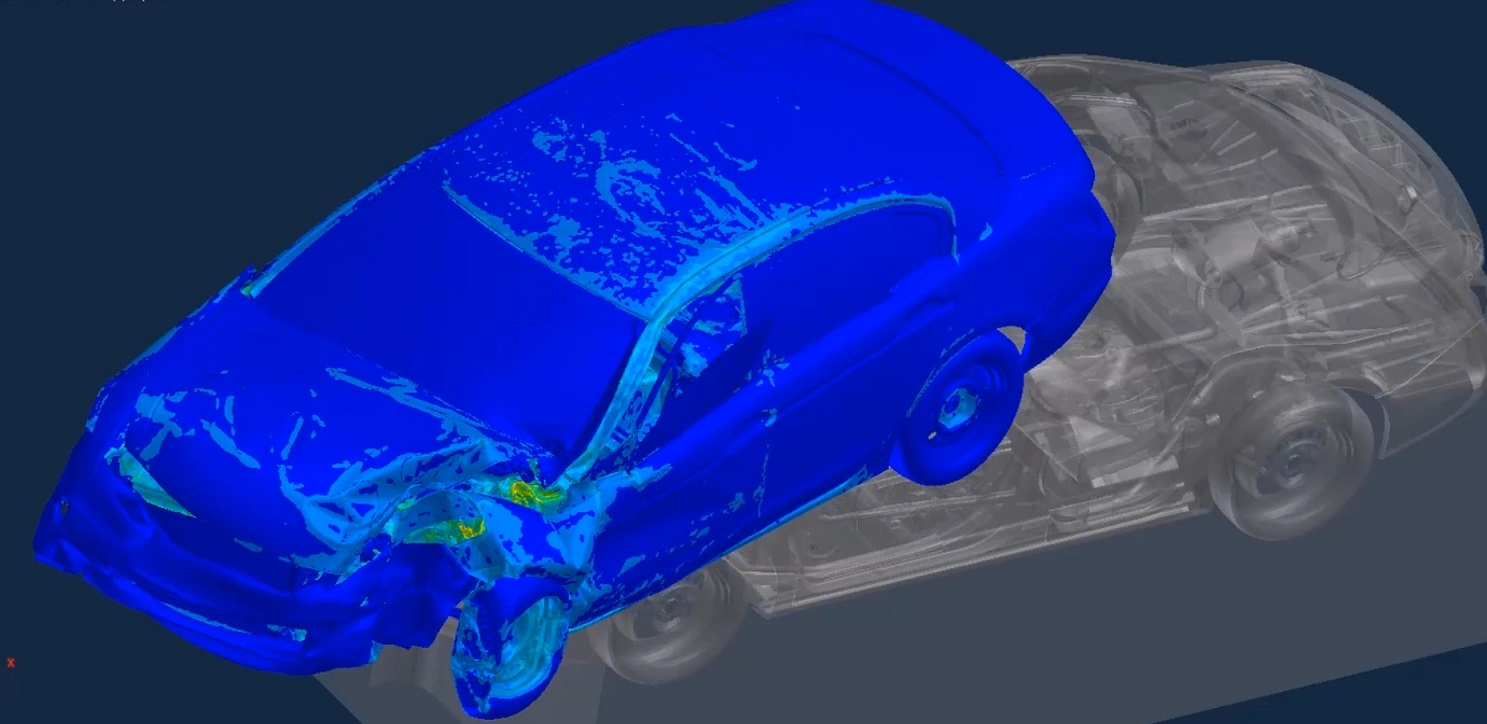

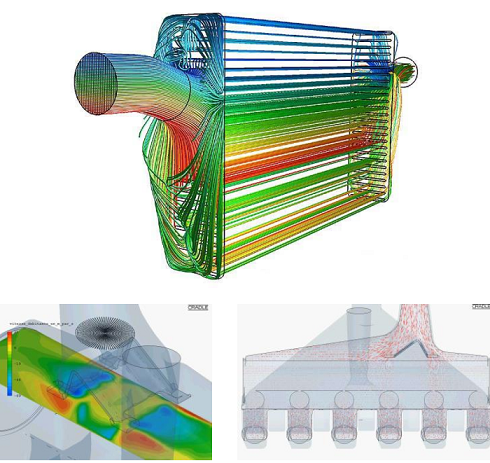

The strength analysis involves evaluating the structural integrity of components and systems, using techniques such as finite element analysis (FEA), to predict the stresses and deformations in the structure. This information is used to determine the safe working stresses and deformation limits for the component, ensuring that it can perform its intended function without failure.

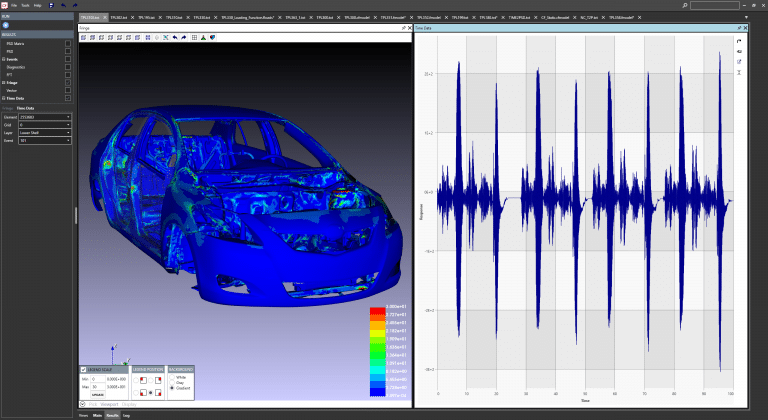

Durability analysis involves evaluating the component's ability to withstand cyclic loading and fatigue, using techniques such as fatigue life calculations and material testing. The analysis takes into account factors such as load frequency, amplitude, and duration, as well as the material properties, manufacturing processes, and assembly stresses.

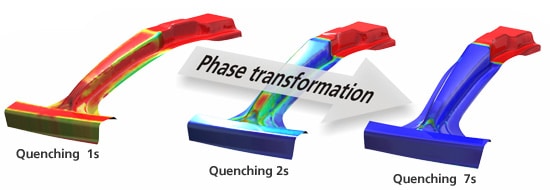

In modern automotive engineering, the analysis is not limited to just fatigue life calculations. The output from the analysis can include safe working stresses, warranty claim curves, and the effects of high temperatures, manufacturing processes, and assembly stresses. This information is critical for optimizing the design and ensuring that the component meets the performance and durability requirements of the application.