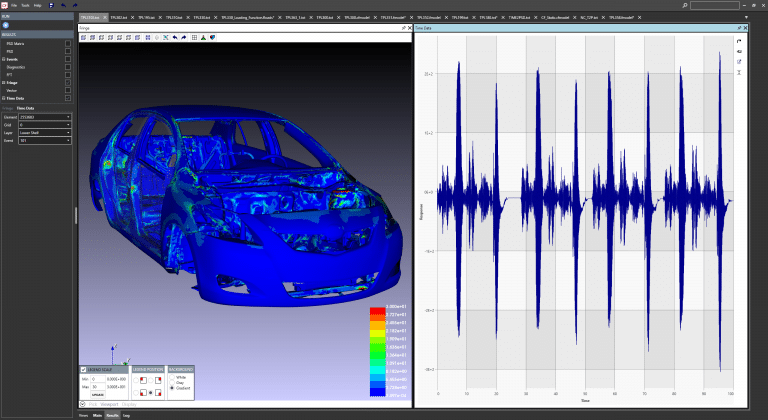

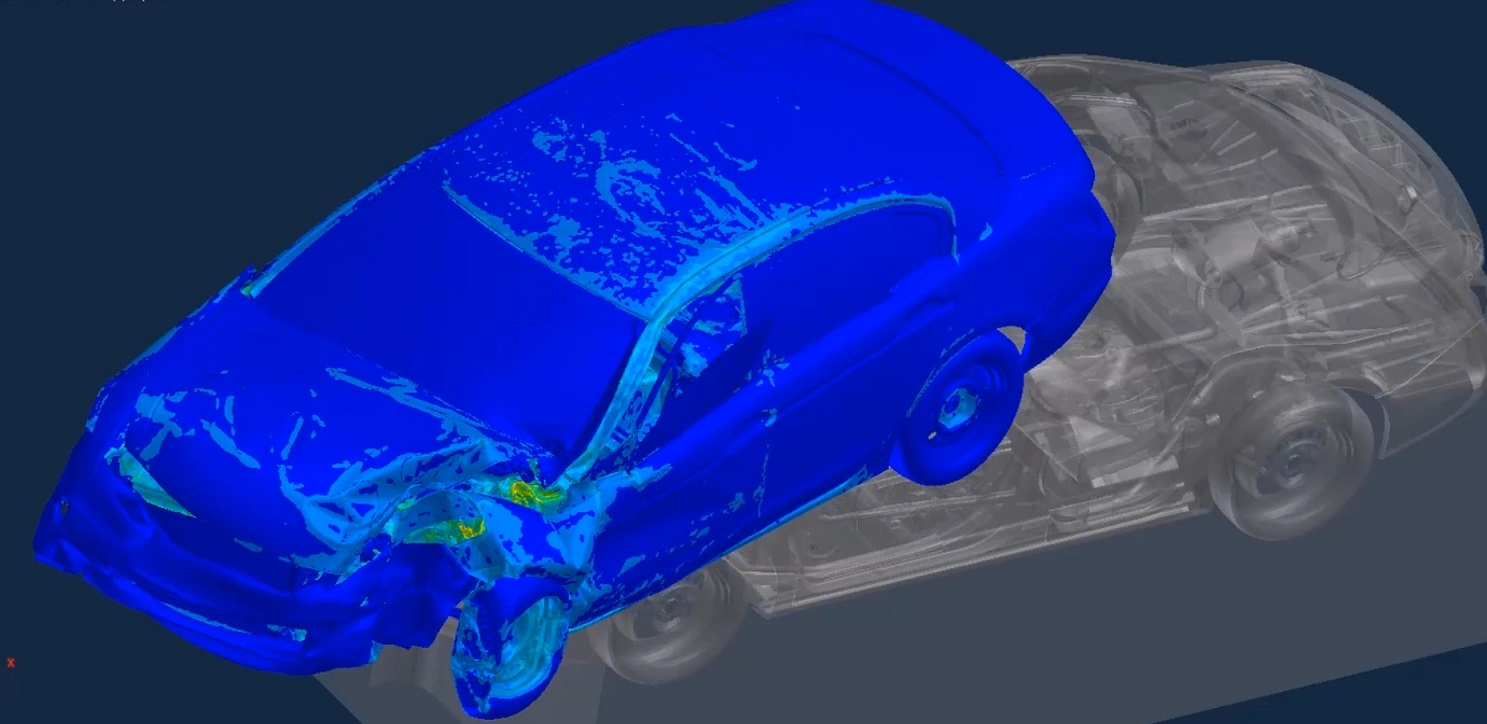

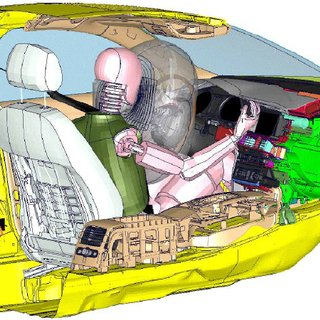

The development of fuel-efficient internal combustion engines in response to global demand for more eco-friendly vehicles has had an impact on the noise, vibration, and harshness (NVH) and acoustic behavior of vehicles. As automotive OEMs and suppliers work to improve fuel economy and reduce emissions, they must also address the NVH and acoustic challenges that arise as a result.

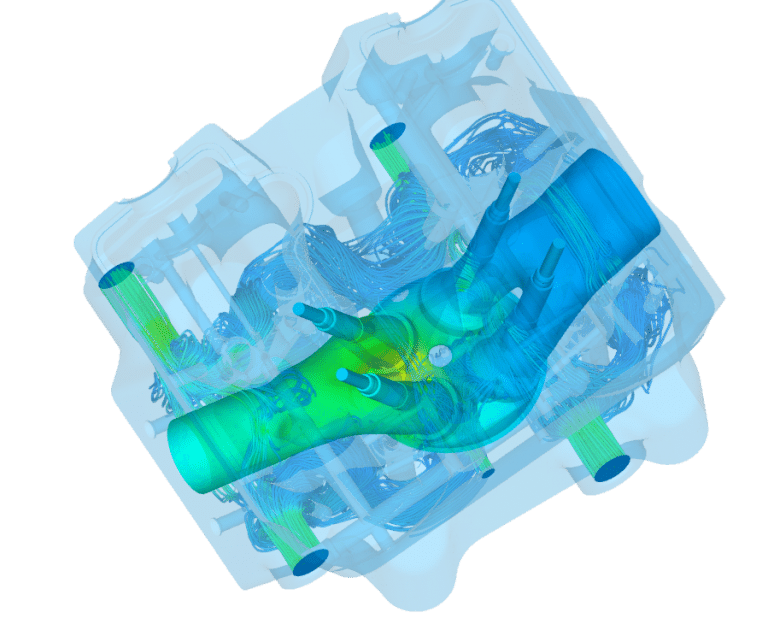

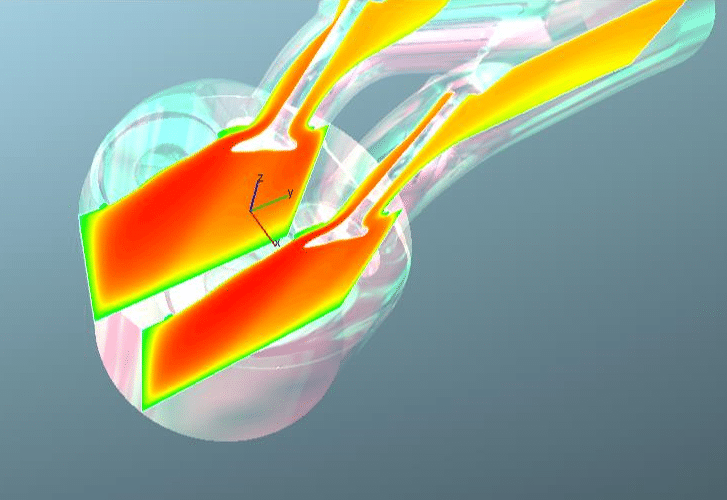

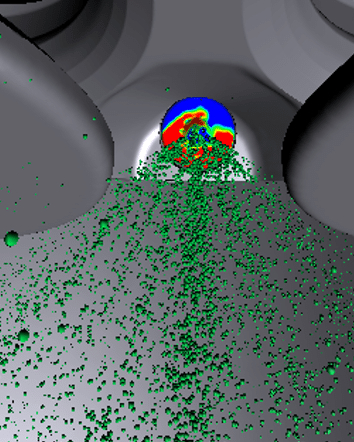

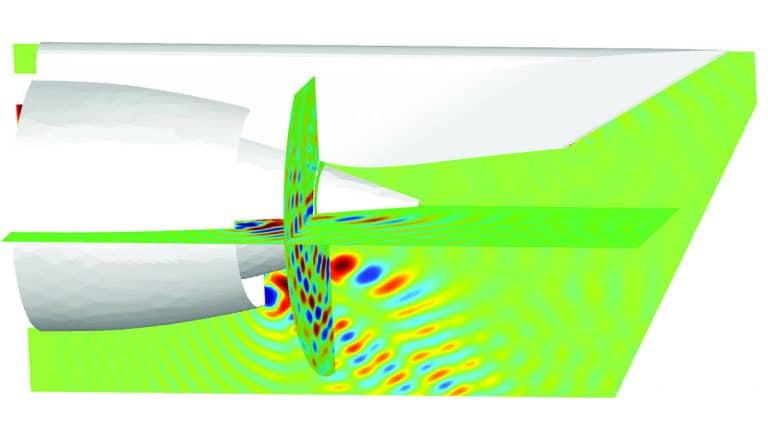

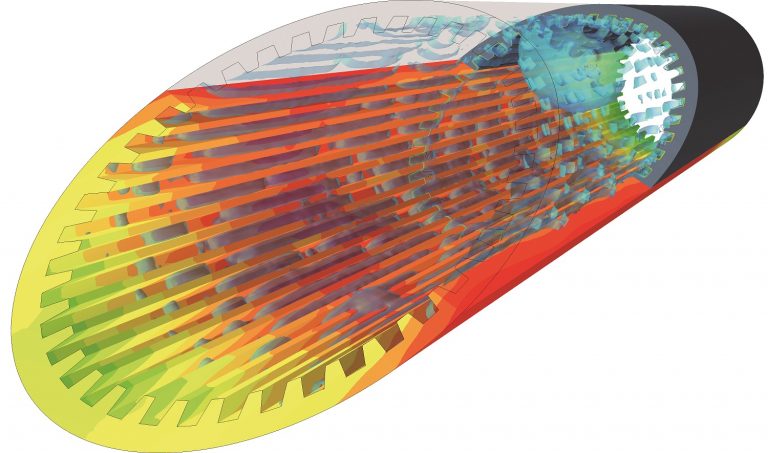

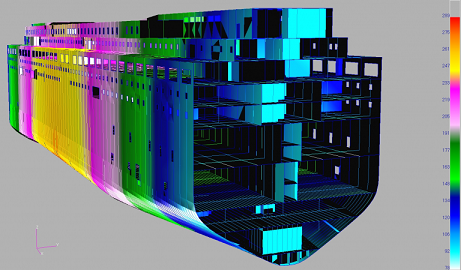

NVH and acoustic simulation plays a critical role in the design and development of powertrains in the automotive industry. By using advanced simulation tools, engineers can identify and address potential NVH issues early in the design process, reducing the need for costly physical prototypes and testing.

One key challenge in powertrain NVH and acoustic simulation is the need to balance conflicting objectives. For example, reducing engine noise may require adding additional sound-absorbing materials, which can increase the weight and complexity of the engine. Alternatively, reducing engine vibration may require changes to the engine mounts or the use of additional damping materials, which can also increase weight and complexity.