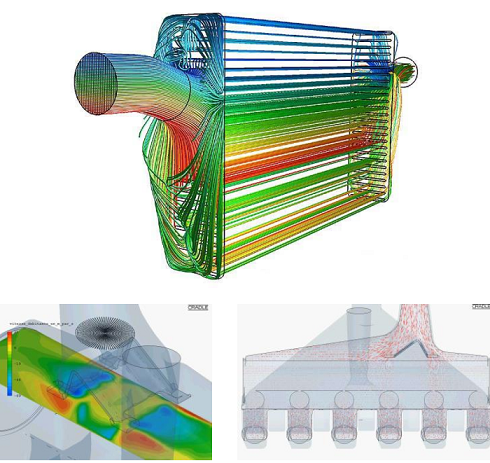

CFD Simulation for Internal Combustion Engines

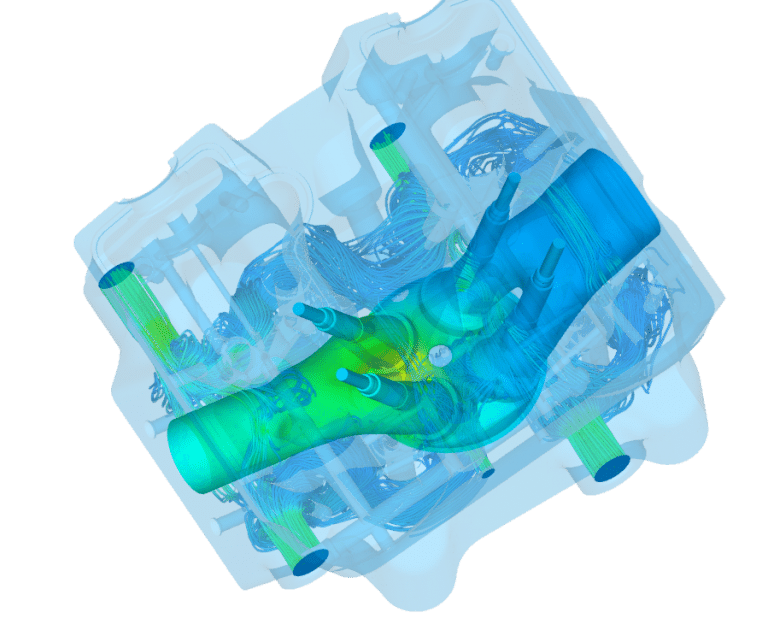

CFD simulation is a powerful tool in the automotive industry for predicting and analyzing flow, combustion, and emission characteristics of internal combustion engines (ICEs). It allows engineers to optimize the design of engines and their components, as well as develop strategies for reducing emissions and improving fuel efficiency.

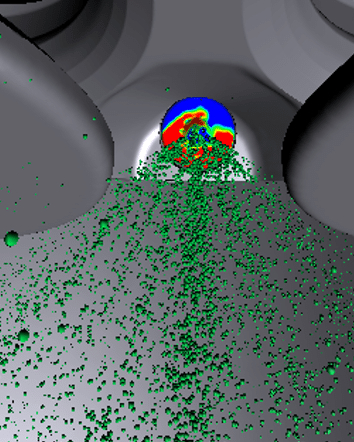

One of the key advantages of CFD simulation is its ability to predict the behavior of fluid flow inside the engine, which is essential for understanding the combustion process. This includes modeling the fuel injection process, air-fuel mixing, and combustion chemistry. CFD can also be used to analyze the performance of different engine components, such as intake and exhaust systems, and optimize their design for improved flow and combustion characteristics.

In addition to improving engine performance, CFD simulation can also be used to reduce emissions and improve fuel efficiency. By accurately modeling the combustion process, engineers can optimize the air-fuel ratio and fuel injection timing to minimize emissions while still meeting performance requirements. CFD can also be used to analyze the thermal management of the engine, including the cooling system and exhaust gas recirculation, to improve fuel efficiency and reduce emissions.

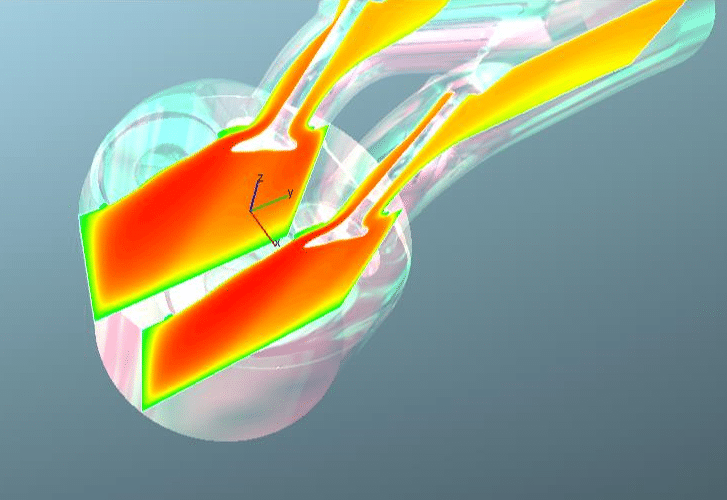

To further enhance the accuracy of CFD simulations, 1D-3D coupling can be used to integrate 1D system models with 3D CFD simulations. This allows for more accurate predictions of flow and combustion characteristics, as well as the thermal behavior of the engine.